Introduction

You probably know “righty-tighty, lefty-loosey,” but we’ve rounded up a few additional tips to help you perfect your screwdriver technique and avoid the wrath of the stripped screw.

If you found this page just a bit too late, twirl on over to our stripped screw removal guide.

What you need

-

Tool used on this step:Mako Driver Kit - 64 Precision Bits$39.95

-

Different screw heads call for different driver types. Whether it be Phillips, Japanese Industrial Standard (JIS), Pozidrive, Torx, Triwing, or plain old Flathead, use the correct driver for your application.

-

Using a driver that’s “close enough”—such as by turning a Phillips screw with a Flathead driver—can sometimes get you out of a bind, but mostly it’s a recipe for trouble.

-

What’s that, you say? That sounds like a lot of drivers to keep track of? Try using a set of interchangeable bits, like the 64 Bit Kit for electronics repair or the Universal Bit Kit for larger applications.

-

-

-

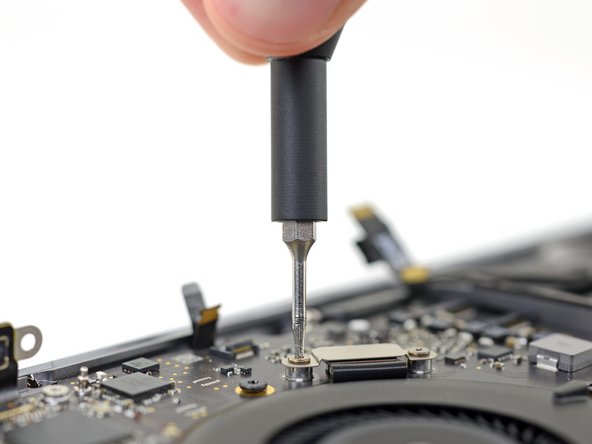

Beginners commonly make the mistake of using a driver that’s too small. An undersized driver slips easily, damaging the screw head and making it difficult to turn afterward—even with a correctly-sized driver. This is known as a stripped screw.

-

An oversized driver fits into the screw only shallowly, if at all.

-

When you find a driver that fits about right, compare the next size up as well as the next size down before you proceed.

-

In general, use the largest driver size that fits snugly into the screw.

-

-

-

Keep your drivers in good working condition by using them only as designed.

-

Prying with a screwdriver can bend or break the tip, making it useless for turning screws.

-

Chiseling with a driver can deform the tip. A damaged driver like this one no longer fits snugly in the screw head, resulting in slippage (and stripped screws).

-

To avoid stripping screws, only use drivers that are in good condition.

-

-

-

-

Whenever you install a screw, first turn the screw counter-clockwise (in the “loosey” direction) to “seat” the screw.

-

Turn slowly until you feel the screw level off and sink slightly, then stop.

-

Now it's safe to tighten the screw.

-

If your screw doesn't tighten easily, back off and carefully re-seat it, and try again.

-

-

-

Finally, use appropriate torque when tightening screws down. A properly fastened screw will be snug, but not so tight that your driver starts to slip.

-

Very small screws—such as those used in phones and tablets—require very little tightening force. As soon as you feel resistance, give it another quarter turn or less and then stop.

-

Cancel: I did not complete this guide.

320 other people completed this guide.

7 Guide Comments

Regardless of whether you are a technician or a DIYer I strongly recommend that you buy the best quality screwdriver possible. Quality screwdrivers will last a lifetime or longer. Poor quality screwdrivers will quickly wear out making them useless and will damage the screws.

Quality brands - in no particular order and what I can recall at present - include PB Swiss, CK, Wera, and Snapon.

Excellent tutorial, Jeff! Thanks for creating this. I’m a 60 year old grandmother, and a widow…finding myself taking on repair projects these days that I never thought I’d ever be doing. But I enjoy tinkering and fixing things, or trying to make something “work better”. So it never hurts to review the basics….some of us missed some details the first time around. Thanks again :-)

I am a newbie to the ifixit community, recently changed the battery on my iPhone 6. I always appreciate the opportunity to review “basic” information on DYI skills and tools to see if I can learn new knowledge, as was the case with Jeff’s tutorial on the use of screwdrivers. :)

Great! Super happy to hear that!! If ever you’d need guidance around here, have questions or suggestions, don’t hesitate to reach out using community@ifixit.com. Right on!