Introduction

To repair the grinder, first open the device. Unscrew the grinder and lift it out. You can then open the grinder, clean it or replace parts (like the motor, sensor or the grinding discs).

What you need

-

-

Remove all attachments, like the water reservoir, the brewing chamber, the bean compartment lid, and the drip tray. Remove all of the coffee beans.

-

Turn the machine around so the back is facing you. Remove the two T10 Torx screws at the bottom edge. Pull out the back at the bottom edge and lift it down.

-

It's important that the parts are readily visible:

-

The motherboard

-

The pump

-

The flow meter

-

The heating element

-

-

-

-

Pull the upper cover out from under the front cover and lay it slightly offset.

-

Remove both of the T10 Torx screws attached to the side covers.

-

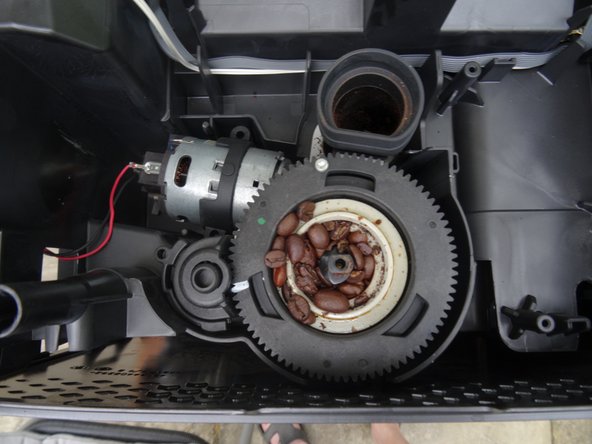

Picture 2 shows the grinder, which can now be easily taken off.

-

If you want to repair the grinder: here are the instructions Replacing the Philips ceramic grinder motor and sensor

-

-

-

Take a photo of the mark on the large gear wheel; it should be in the same position when you reassemble it.

-

Although the motor is powered by 230 V, diodes ensure that only positive half-waves are supplied, so that the motor only rotates in one direction. Make a note of how the connection cables are plugged in. Test later to see if it is rotating in the correct direction.

-

You can test the motor with approximately 25 V DC. It should turn easily and draw approximately 120 mA. If this is not the case, check the carbon brushes on the side. Only then should you consider replacing it.

-

Insert translation here

-

Any brackets—in this case, the black rubber sleeve—must be transferred to the new part.

-

The speed sensor can only be removed from the inside. To do this, you must disconnect its plug from the main circuit board and expose the cables.

-

-

-

There are four Torx T10 screws on the underside of the grinding mechanism. Remove those.

-

The screw marked in yellow must not be removed when replacing the motor.

-

The white plastic sleeve around the screw marked in yellow must be transferred to the replacement part.

-

Lift off the motor.

-

-

-

The machine's electronic use the sensor to measure the number of revolutions. The sensor must be transferred to the new motor.

-

The sensor is secured on the inside with a locking tab. It can therefore only be removed from the inside.

-

Press the locking tab firmly down with a flat screwdriver.

-

Slide the sensor out, using the flat screwdriver to help if needed.

-

Transfer the sensor to the new part.

-

-

-

Grease the worm gear on the new motor a little; the old grease may be sufficient, but new grease is better.

-

Check that the plastic bushing is seated properly in the center opening. Screw the motor tight.

-

Follow the steps in reverse order to reassemble your device.

Cancel: I did not complete this guide.

4 other people completed this guide.

Special thanks to these translators:

100%

These translators are helping us fix the world! Want to contribute?

Start translating ›

1 Guide Comment

SAECO SM 7685 xelsis . Maalproces wordt bij electronische inschakeling direct gestopt . Error 1 soms 2 .

Maalwerk uitgenomen en super schoon . Niet aangetroffen de stekker verbinding toeren sensor , draden zitten er gewoon niet .

Durf bij u geen nieuw maalmechaniek te bestellen. U hebt het wel .

Printplaat in gebreke ?? Graag reactie , dankuwel. a.judinavanvuuren67@kpnmail.nl. ( a punt judina….. )