Introduction

UPDATE 6/6/18 Someone makes a replacement piece! Masica, thank you for the tip! Look on eBay for “DS-560 shaft” and it came up right away from seller g_loc.

For the workaround you need only a staple, bent straight -- or a straight pin. For the repair with a paperclip you will need two very small flathead screwdrivers for prying and one normal Philips head screwdriver and a pair of pliers or two. You will be removing the outer shells of the two main body pieces, removing a small shaft and bending a paperclip around the shaft to make it fit tightly in place again.

THE PROBLEM: In the front section that you pull up on the gray lever to allow to swivel out about 30 degrees --it's the section that says Epson on the front and has the lights-- a piece went bad in there. Here's the gist-- in order to pull just one sheet at a time, the rollers in the front panel must not move until the last sheet; they provide friction as the scanner pulls the sheets underneath out. What's happened is that one piece that's supposed to hold the roller from moving has failed and the roller now rolls and therefore the whole stack comes through. A small plastic shaft has tabs that have become splayed on one end and won't hold the rollers in place.

It should be easily replaceable -- almost without disassembly, but the Epson parts diagrams don't show this piece separately so I haven't found a place to buy a new one.

What you need

-

-

This first few step are a WORKAROUND, the repair guide starts at step FOUR. Use this if you're desperate and absolutely need it to scan hundreds of pages RIGHT NOW. Open the front panel by pulling the gray lever as indicated.

-

NOTE: One person posted that this worked for them without it jamming and is therefore their permanent fix so try this first.

-

From Saul Rosenthal: "[can do it] without disassembling any of the covers. Go directly to the rollers and remove, then follow removal of the stub shaft for your repair. Assembly required that the DS-510 be put on its side looking down into the access hole and ensure that the interior shaft is there to engage and complete assembly and reinstall rollers."

-

-

-

Inside, on the back of the panel you just opened, you will see two identical foam rollers. Stick a straightened staple or straight pin through the foam so they won't be able to roll anymore once the pin hits the bar between them. NOTE: One person posted that this worked for them without it jamming, so try this first.

-

-

-

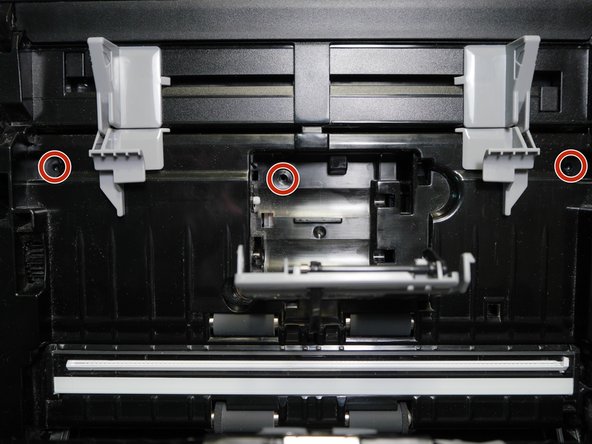

THE REPAIR: There are 4 screws on the front panel's cover that we need to remove, but they're not accessible until you remove that whole panel from the main body of the scanner. The screws nearest where it hinges are the ones that are tough to remove.

-

If you have a very low-profile ratchet you may be able to get to all four without having to remove the front panel. If so, skip straight to step 7.

-

-

-

find and remove the three screws on the bottom of the main body-- you will need to extend the tray all the way out to access one of them. Then there are three more screws up above, on the main face of the scanner, where you place the sheets to be scanned. One is beneath the replaceable roller, two are behind the gray paper width sliders

-

-

-

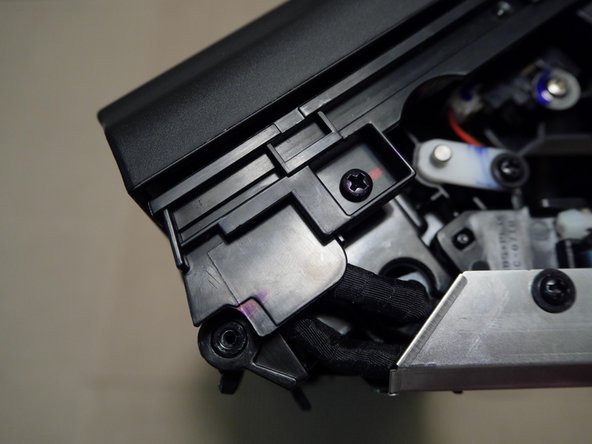

There is a third screw at the very front of the base that is hard to reach even with the tray pushed all the way forward.

-

You can remove the base completely by sliding it forward and prying up on the two large clips on either side.

-

This provides easier access to the third screw at the front of the base.

-

-

-

-

Once that's accomplished you pull the main body of the scanner OUT of its wraparound shell (back, bottom and sides), using a small pry tool to help pop the shell loose around the edges. It's tough plastic so you probably won't break anything, and it's mostly hollow too so don't worry about where the screwdriver goes inside of it while you're prying

-

Seen here is the shell once the "guts" are out of it.

-

-

-

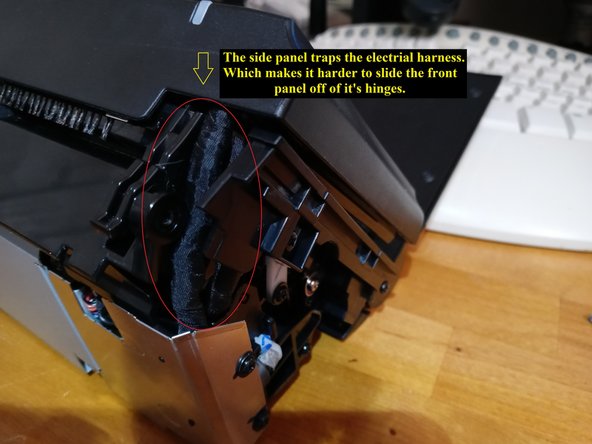

The side panel traps the electrical harness and interferes with sliding the front panel off of it's hinges.

-

Removing the side panel makes it a lot easier to slide the front panel put of its hinges.

-

This leaves plenty of loose harness to lay the front panel face down next to the base.

-

-

-

Raise the front panel to about 45 degrees or until you can slide the panel all the way to the left.

-

This allows you to lift the right hinge out of the notch in the hinge as shown in the picture.

-

You can then slide the entire panel to the right and it will slide it out of the left hinge.

-

-

-

Remove the four screws and use a small flat tool to pop/pry the cover off of the panel. The gray bar that runs inside, that has on it the lever to open the panel-- because of its springs you should keep it attached to the panel and NOT the cover. You can pop it out of its groove in the cover you're removing and thus not need to take the spring off.

-

-

-

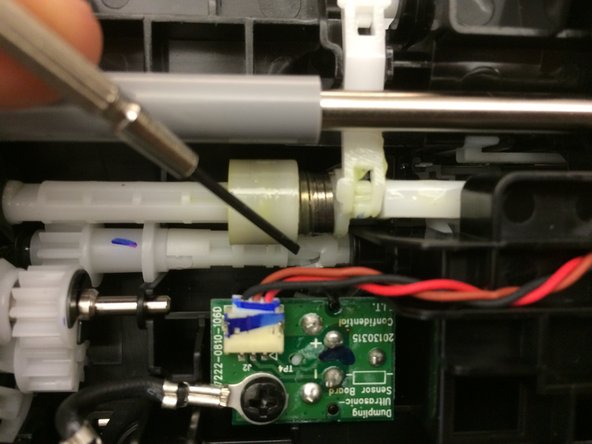

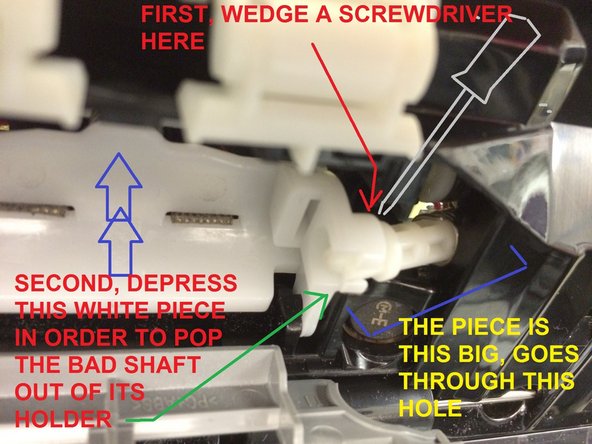

Keep the screwdriver in place as you simultaneously depress the carrier that the rollers were in. That will pop the bad shaft out of its groove. You can only do this while the shaft is turned one particular way, however; otherwise it has tabs that make it too wide to come out of the groove, so you may need to turn it by hand which is not difficult.

-

-

-

I used parts from eBay seller "g_loc". They are interchangeable with the Epson parts. My fix has the original Epson inner shaft and the g_loc outer shaft.

-

You can also fix the Epson part using a variety of methods: a paper clip, heat shrink tubing, small spring (like from a pen), aluminum duct tape, thin fiber-glass tape impregnated with JB Weld let dry overnight, short length of copper pipe or a plastic straw. See the comments for this section and the general comments for more ideas.

-

For the paper clip fix, using pliers, tightly wrap a paperclip around the shaft you have removed. Wrap it near the end that is NOT splayed out, then pull it up to the end which IS bad, as you move it up, it will squeeze the splayed ends back in place.

-

Be careful if you use the heatshrink tubing fix. I tried it and melted the Epson inner shaft in seconds. The pen spring fix seems much safer.

-

-

-

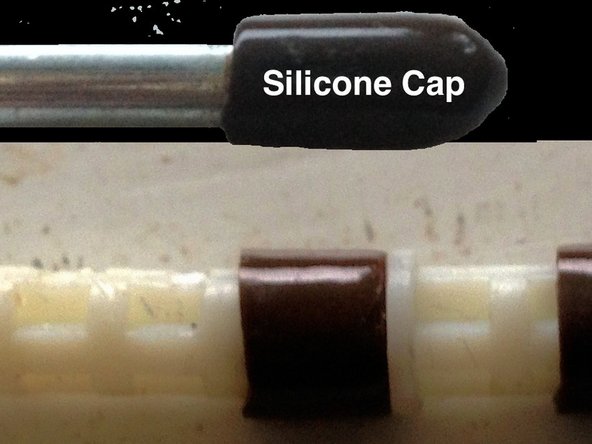

I used silicon caps (for 5 mm diameter shelf pins) such as the one shown here. Cut the closed end to obtain ~ 0.75 cm length cap and inserted them over the plastic parts at the two joints. It was a snug and secure fit.

-

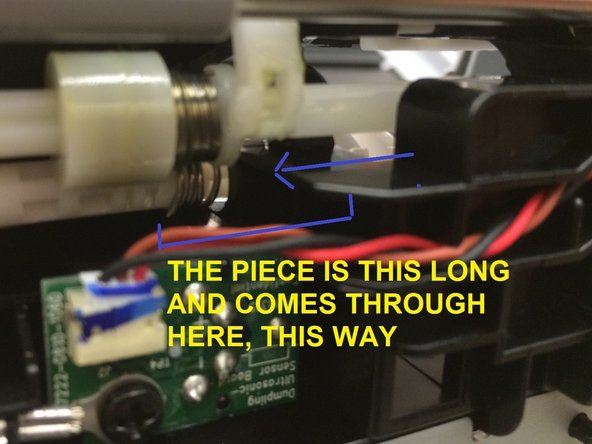

Inserted the long plastic components from the side shown in the second image and secured in its slot first on the other side before pushing it out with a flat screw driver and inserting it into its slot on this side shown in the image. It ran smoothly after the fix. It remains to be seen how long it will last.

-

Another user, Eric Hargis, recommends as another alternative putting an old spring over it

-

Yet another user, lszablya recommended a different twist: "I used double wall heat shrink tubing. Looks like it sucked in around the prongs just fine."

-

-

-

The original poster on Amazon who inspired me to try this fix (and if I could find his name I'd give him credit) recommended tightening up the defective piece with some string tightly wound around it and then caulking it to keep the string from getting caught up in things, but I'm doubtful about it holding up long-term.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

31 other people completed this guide.

81 Comments

I'm surprised no one else commented on this. Awesome article - worked perfectly. It's a bit tricky and I wouldn't recommend this for a rookie with tools, but it saved me. I couldn't find the part for this thing nor could I find a repair shop to work on it. It's funny how it started clicking 3 weeks out of warranty! THANKS FOR THE POST! and the effort. awesome!

Thank you so much for the detailed instructions. I found a replacement part on Amazon and together with that you've saved me hundreds of dollars.

thank you very much for posting this. was scratching my head for an hour, after reading your post, took 5 minutes to fix and get it going. what a relief. technical phone support was useless, troubleshooting was useless. scanner would have probably ended up in the trash if not for you. thank you!!!