Introduction

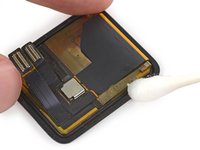

Unfortunately, opening up your Apple Watch may damage the Force Touch sensor, which also serves as a gasketing seal. The sensor is made up of two layers, glued together. These layers may separate when you open your watch, compromising its seal after reassembly. If this happens, you'll need to repair or replace the sensor before reassembling your watch.

What you need

-

-

Before starting repairs, take your watch off the charger and power it down.

-

-

-

Prepare an iOpener (or grab a hair dryer or heat gun) and heat the face of the watch until it's slightly too hot to touch.

-

Leave the iOpener on the watch for at least a minute to fully heat the screen and soften the adhesive holding it to the case.

-

-

-

Place the curved section of the blade in the gap between the glass and case on the lower edge of the watch face, and press firmly straight down into the gap.

-

When the glass has lifted, gently rotate the knife down, opening the gap more by pushing the glass up.

-

-

-

-

Use scissors to cut one of your opening picks to about the width of the battery. Try not to leave any sharp corners.

-

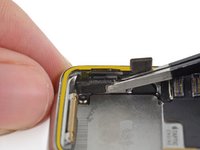

Insert the modified pick between the right side of the battery and the case.

-

Use constant, steady pressure to slowly pry the battery up, separating it from the adhesive securing it to the system board.

-

On the larger (42 mm) models, it's possible to accidentally pry at the system board underneath the battery. Insert the pick only far enough to get underneath the battery, not the system board.

-

If needed, apply a little high concentration isopropyl alcohol (90% or greater) around and under the battery to help weaken the adhesive.

-

-

Tool used on this step:Tweezers$4.99

-

Steady the bracket from the left side using your fingers or tweezers.

-

At the same time, insert a small (1 mm) flathead screwdriver under the tiny tab on the right.

-

Finally, place one finger behind the tab, and pinch the bracket hard between your finger and the screwdriver to detach the cover.

-

-

-

Use a Y000 driver to remove the single tri-point screw securing the Force Touch sensor connector cable.

-

-

-

Use tweezers to peel up any adhesive left behind on the lower case.

-

Clean all traces of adhesive (and broken glass, if any) thoroughly from the case before re-sealing your watch. Scour the case using the tip of an opening tool or spudger wrapped in a lint-free cloth or coffee filter, along with a little isopropyl alcohol (90% concentration or greater).

-

-

Tool used on this step:Tesa 61395 Tape$8.95

-

If needed, try re-using the existing adhesive to secure the battery. Alternatively, try a small piece of double-sided tape such as Tesa 61395, or a dab of liquid adhesive such as E6000.

-

Rotate the battery down into its slot, and press it into position.

-

Press the battery down against the system board to re-adhere it in place.

-

Take your e-waste to an R2 or e-Stewards certified recycler.

Repair didn’t go as planned? Try some basic troubleshooting, or search our Answers forum for help.

Cancel: I did not complete this guide.

244 other people completed this guide.

45 Guide Comments

I can't stress enough how important it is to not flex the digitizer ribbon cable. A cracked ribbon cable will necessitate replacing the entire lcd.

This is a Fact. It happened to me when the whole rig hit the floor lol

If there is a new induction frame - do not use double-sided adhesive tape.

How can I tell if there is a new induction frame?

By Induction Frame, what do you mean, exactly?