Introduction

Lens repairs are generally very difficult, but the first stage - taking the back off - is more straightforward and there s a small chance it will reveal a fault.

What you need

-

-

Remove 2 screws on the right hand side of the case.

-

Remove 2 screws on the left hand side of the case.

-

-

-

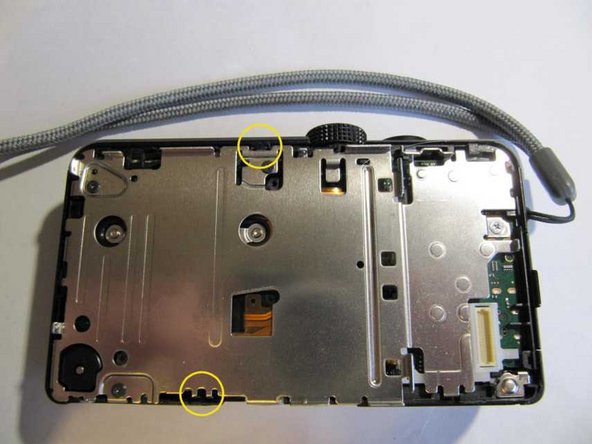

Remove 2 screws on the bottom of the case, adjacent to the tripod mount. Note that these screws are slightly shorter than the previous ones and so should be kept separate.

-

Ease off the case back. You can help it off by inserting a spudger in the crack on all sides to ease it, especially either side of any points where it seems reluctant to come.

-

-

-

Gently lift the locking bar on the LCD ribbon, then ease the ribbon out of the socket.

-

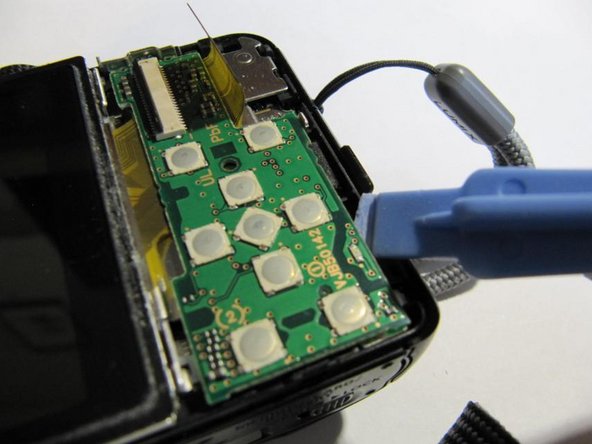

Lift the buttons board by inserting a spudger under the bottom right hand edge. This will detach it from a connector beneath.

-

-

-

Release a clip on the left hand side of the LCD and hence lift the LCD out.

-

-

-

Remove 3 black screws from the mid plate.

-

Remove one silver screw from the right hand side of the mid plate.

-

Remove the mid plate, carefully releasing it from plastic clips on the top and bottom edges.

-

-

-

-

If required, you can now lift out the lens assembly.

-

If you suspect dust or contamination on the sensor or IR filter you can go on from this stage to clean them without removing the lens.

-

The symptoms are one or more dark patches at the same place in all images and at all levels of optical zoom, but getting bigger and possibly moving out of the image on digital zoom. If the patches are fuzzy then the contamination is probably on the IR filter but if well defined, it's more likely on the sensor itself.

-

A video at https://youtu.be/0nmwt0frZns shows the procedure for a different but similar model of Lumix camera. One difference is that you will need a small Torx rather than cross-head screwdriver (I think T4 or maybe T3 but unfortunately I forgot to make a note of which).

-

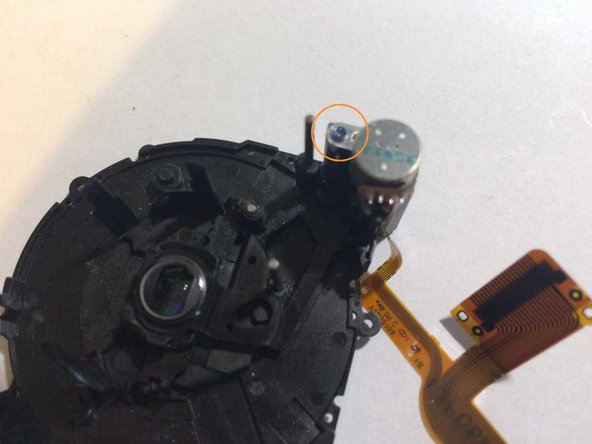

With the lens removed you may be able to test the zoom by applying a 3V battery to the terminals on the bottom of the zoom motor, which is mounted on the side of the lens. Reverse the polarity of the battery to reverse the direction of motion.

-

-

-

Before starting you should ensure that the lens is fully closed. If not, you can close it by applying 3V from 2 AA or AAA alkaline cells to the zoom motor as shown. Apply positive to the terminal nearest the lens barrel to close it, or the other way round to open it. For a sticky lens you can use up to 5V, for example from a USB charger.

-

The lens cover should now be fully closed. (It needs to be fully closed otherwise reassembly will be very difficult if not impossible.) Tape it shut, but make sure you use tape that can be easily removed without bending the lens cover blades.

-

-

-

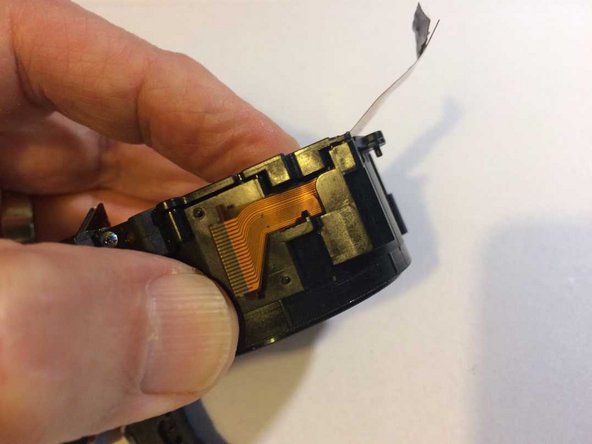

Lift the black locking bar and hence disengage the ribbon from its socket on the bottom of the lens. Lift the branch of the ribbon holding the socket off the pegs which retain it.

-

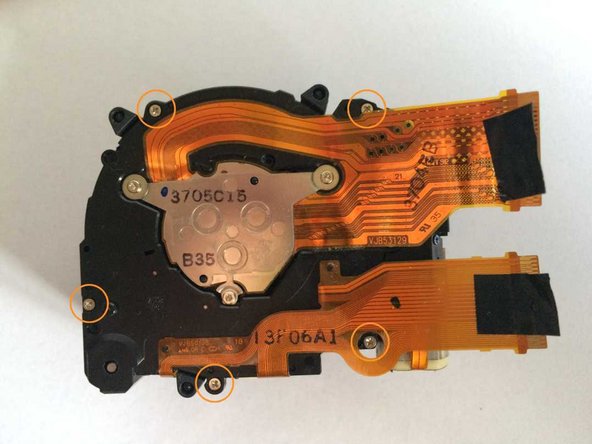

Remove 5 screws from the back of the lens.

-

-

-

Whilst holding the back of the lens to prevent it springing open, and holding the zoom motor in place, remove a 6th screw from the lens back.

-

Place the lens face down on the workbench.

-

-

-

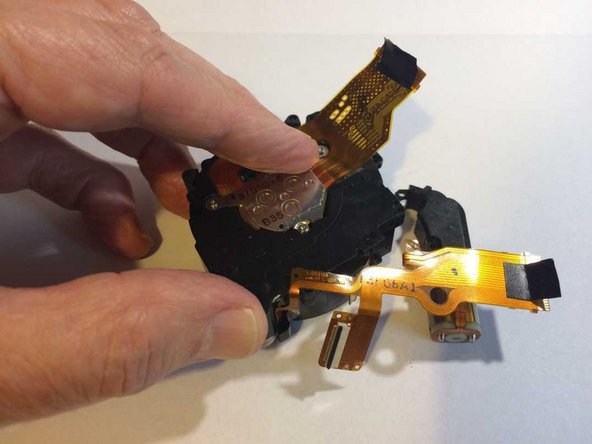

Gently list the lens back off. It is now completely separate from the lens barrel.

-

On reassembly, ensure that the ribbon from the barrel is correctly tucked into its pocket before offering up the back.

-

On reassembling the back, make sure that it's correctly aligned with the barrel. It may take a fair amount of jiggling to get it to go fully home, and if you didn't fully close the lens before starting it may be almost impossible.

-

On reassembly, ensure that the ribbon from the barrel which you tucked into its pocket is correctly positioned and not pinched before inserting the screws.

-

-

-

To remove the focus motor, first remove the screw retaining the focus motor end stop detector and lift out the detector.

-

Remove the screw holding the focus motor in position, and remove the focus motor. The focus lens will spring up.

-

You can now examine the focus motor lead screw. Check the nut on it moves up and down on the lead screw as you turn the lead screw with your fingers. On a very heavily used camera it may be possible for the thread in the nut to wear out and slip.

-

Before reassembly, return the leadscrew nut to its original position close (but not too close) to the end of the lead screw. Ensure that the focus lens holder is correctly positioned on its guide posts before refitting the focus motor.

-

-

-

Disassembly (or rather, re-assembly) of the lens barrel is likely to be very challenging. You can get an idea of what would be involved from the guide Canon PowerShot SX200 IS Lens Disassembly. Do not attempt it unless you are prepared to spend as long as it takes and have almost unlimited patience!

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.