Introduction

This guide may be useful for users who are experiencing power issues. This procedure requires a high technical skill in electrical soldering, along with moderate electrical wiring skills.

What you need

-

Step 1 Base Removal

Careful: steps 1-5 are sourced from a guide that's marked as in-progress.

-

Hold the food processor upside down and remove the two screws indicated with a screwdriver. Once unscrewed, remove the two rubber suction pads.

-

-

-

-

Use a regular nylon spudger to remove the plastic caps at these locations with moderate pressure.

-

-

-

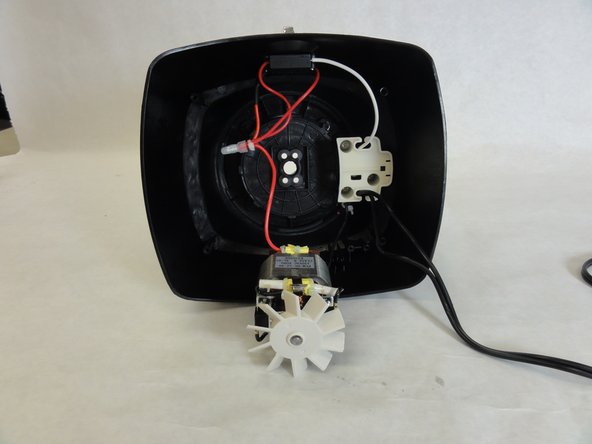

Solder the highlighted section of the power cord, and undo the wiring. Using soldering wire connect a new line with the soldering iron.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.