Introduction

Credit for images and text goes to our partner, Bondtech AB

-

-

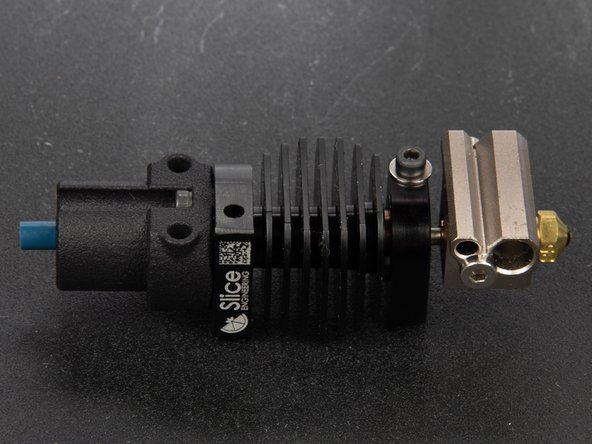

Use 2x 2.5x6mm screws supplied with the Copperhead™ hotend.

-

Insert them in the mounting holes.

-

-

-

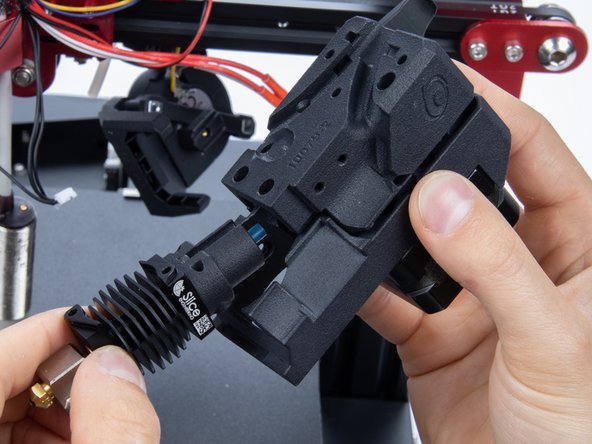

Attach Adapter and hotend.

-

New lineNotice the orientation of the Adapter and Hot Block.

-

These indented marks should be oriented towards the front of the DDX.

-

The fixation screws that attach the DDX to the carriage plate will enter through them.

-

-

-

Insert the Capricorn tube inside the Adapter and hotend.

-

Push hard until it hits the bottom.

-

-

-

-

Insert the Capricorn tube in the cutting fixture

-

Drive it until it fits the Adapter

-

Pressing all together use the hobby knife to cut the tube straight.

-

At the end, the Capricorn should stand out about 5mm.

-

-

-

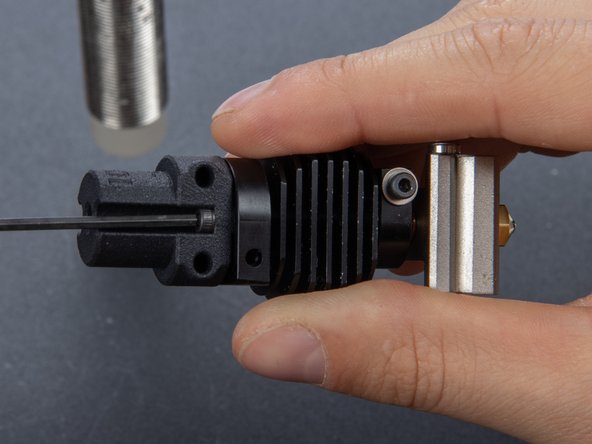

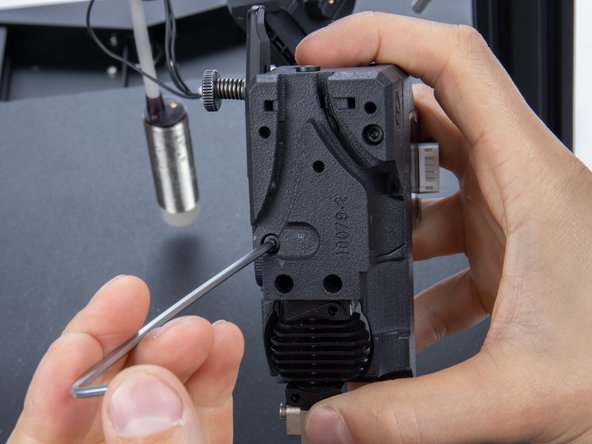

Spread the housing apart from 2 to 3mm

-

Insert the Copperhead™ in at an angle.

-

Push it until the mounting holes align.

-

-

-

If when clamping the DDX the gears collide:

-

Release the thumbscrew.

-

Open the hinge.

-

Clamp both halves while rotating the main gear back and forth.

-

-

-

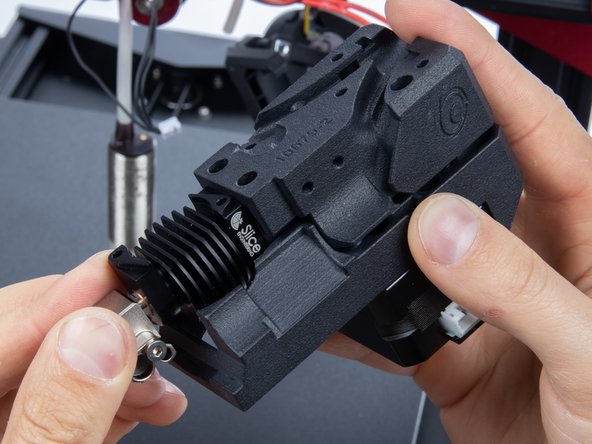

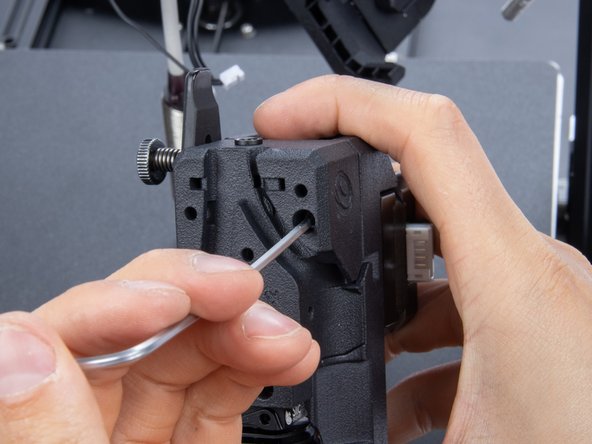

When the DDX closes down verify the mounting holes alignment.

-

Screw the back screws to close it.

-

To reassemble your device, follow these instructions in reverse order.

2 Guide Comments

where do i get the cutting fixture

Thanks for your questions. We’ve added a link to step 3.