How to fix Broken Internal Display Connector on iMac 27"

Hi,

I have a 27” iMac 27 that one of my coworkers has damaged the display connector while pulling the LCD hard and snapped some pins from the board.

This was done while I was replacing a hard drive that failed. "Common thing with the iMacs."

Before coming here I have Googled the problem, read so many forums and found a post in Macrumors.com, where people had this issue and fixed it by ordering a new connector and soldering it on.

I went ahead and ordered that connector, when i got it I quickly start soldering it. Unfortunately it is a bit challenging and spent days to get right without bridging it, but it is impossible.

I have become so impatient that I want to throw the whole thing in the garbage, but I have got so many video projects to do being a video editor.

I want to know if other people are experiencing this issue, and how to they dealt with it. Also if there are anyway repair places that I send the logic board and they fix it for cheap, I know how much Apple is demanding and I just can't afford that.

Thank you in advance for any replies.

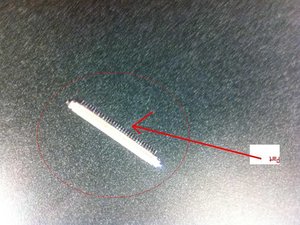

I have attached some photos for reference:

Dedicated GPU

The solder joints

The part

Is this a good question?

2

2  1

1  1

1

3 Comments

I'm in the same position with you right now , it's looking I will have to replace the cable also has it's lost two of the gold coverings . I've looked In to having it professionally done but sadly they said it needed the whole motherboard replacing , and then offered to purchase the machine off me for a few quid.

So I've started having a go myself. The issue is when I go to insert the lvds cable the force I have to apply to get it in breaks the connector again.

Waiting for the 2nd connector to come.

Any advice welcome

by chrisconnell

chrisconnell - I understand you succeed in soldering the new connector, do you have any hints on how to succeed?

ciao solos

by solos

It very simple if you have the right equipment, unfortunately you need a 500 quid microscope and the correct soldering iron and the correct solder and the correct method not to mention a hot air station 500 quid, the correct flux etc then its easy

by tn21