How to repair this failed induction cooker?

My induction hob failed while in use. It blew the circuit breaker, and since then it blows the breaker immediately on being plugged back into the power.

The ventilation to its underside was not good, so I think that overheating might have caused the failure.

Inside, there's a main PCB, a control/display PCB, a fan, and the induction coil assembly. There is no "hard" power switch - it's all controlled by the capacitative touch-buttons.

The coil measures 0 Ohms (I think that's probably normal), and the assembly has two sensors in the centre - one is a temperature sensor (green wires), I'm not certain about the other. Possibly to detect that an induction-capable pot is on the cooker?

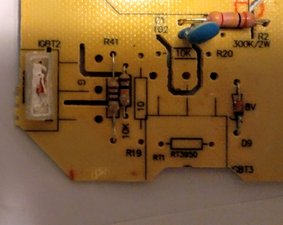

The main PCB is physically divided into the low-voltage control electronics, and the high-voltage coil supply.

When I disconnect the induction coil from the terminals, the device no longer causes the fuse to blow, and the display lights up normally, so I think the fault is somewhere in the supply to the coil. That supply contains some large capacitors and a couple of large transistors (the heatsink has been removed from those in the above photo).

None of these devices look damaged, and the solder joints and PCB traces all look fine.

Can anyone help me work out where the fault lies? My multimeter measures about 600V AC across the open coil terminals when the stove is switched on. But with the coil connected, the fuse/circuit breaker blows before I even have the chance to switch it on. I think there is a relay on board (I hear it switching when I plug it in) - maybe the black device at the top right? Maybe the control electronics use it to switch the coil supply on?

Update (09/05/2017)

I'm removing some of the components from the board, so I can test them and hopefully find what's broken. The two components that were attached to the heatsink are:

- D25SB100 - apparently a glass passivated bridge recitifier.

- IHW20N120R3, a Reverse conducting IGBT with monolithic body diode.

Hidden below the IGBT is a component which I think must be a thermistor (covered in white (thermal?) goop on the left).

I tried to remove a capacitor to test, but it's not only soldered in, but the terminals also seem to be riveted through the holes in the PCB.

Anyone got any ideas which components are most likely to have failed, so which to look at first?

Is this a good question?

5

5  1

1

11 Comments

glad to hear you resolved this problem.

now maybe you, or some other viewer of this item, could help me diagnose a SunHow IH-700C countertop cooker.

this appears to be some kind of orphan product which was never intended for export to the US market (where i am.) i found it in a dumpster and it has a US (2-prong, flatblade, looks like 120V) plug. the characters on the control panel are in some Asian-looking character language.

when i plug it in, it lights the panel lights (no digital display), and when i press a button that looks like a 'go' button, it beeps about once per second for a minute or 2 and flashes some of the panel LEDs, then shuts down (with a cast iron pan on the cooking surface.)

a reference i found on the web says SunHow is a trademark of SunPenTown International, with an office in City of Industry, Calif, USA. however i was not able to find any repair info or circuit diagram for this machine on the web. Sunpentown disavowed any knowledge of this product.

(further comment to follow)

by chriswitt94702

looking around further on the web, i found a discussion of the sensor under the center of the cooking surface. one poster said it was a 'diode', designed to sense temperature, but that did not seem likely to me. i thought it more probable that this is a thermistor.

the component in my cooker showed infinite resistance in both directions at room temperature. shorting its leads led to the same cooker behavior.

i tried substituting a variable resistor of 18k -0 ohms, and got no change in behavior while varying the resistance over the full range. while i was doing this, the voltage across the leads varied from about 4.2 vdc down to less than 1 vdc. (ocv = about 4.5 vdc). anybody got any ideas? thanks

by chriswitt94702

Did you ever have it working, Chris? Most electronic cookers I've seen tend to switch themselves off after a time if accidentally switched on - maybe you need to set a temperature, time, etc.?

Yeah, certainly you should have an induction-capable pan on the stove - mine also beeps and switches off if the pan is removed.

You saw the circuit diagrams in my answer? I know it's a different cooker to yours, but maybe has some hints on how the sensor is supposed to work.

Sorry I can't be of more help!

by Matt

thanks for your suggestions, Matt. no it never ran while in my possession. i did put cast iron on the surface while testing. it would not heat no matter what buttons i pushed. i will look over your circuit diagrams again to see if any alternative answer suggests itself. yes i agree the circuits are quite likely to be similar across different makes, just as most microwave heating (not necessarily control) circuits are.

by chriswitt94702

happy holidays

by chriswitt94702

Show 6 more comments