Craftsman Mower Model 917.289240 is a YTS3000 with a hydrostatic drive. The issue your mower displays appears to originate in the transaxle. I am sure that you already checked all the belts etc. so it is possible that you may have to purge the air out of the system. the instructions for that should be in your owners manual. If you do not have it, this should work for your mower:

To ensure proper operation and performance, it is recommended that the transmission be purged before operating tractor for the first time. This procedure will remove any trapped air inside the transmission which may have developed during shipping of your tractor.

IMPORTANT: Should your transmission require removal for service or replacement, it should be purged after reinstallation before operating the tractor.

1. Place tractor safely on a level surface - that is clear of objects and open - with engine off and parking brake set.

2. Disengage transmission by placing freewheel control in disengaged position (See "TO TRANSPORT" in this section of manual).

3. Sitting in the tractor seat, start engine. After the engine is running, move throttle control to slow position. With motion control lever in neutral position, slowly disengage clutch/brake pedal.

CAUTION: At any time, during step 4, there may be movement of the drive wheels.

4. Move motion control lever to full forward position and hold for five (5) seconds. Move lever to full reverse position and hold for five (5) seconds. Repeat this procedure three (3) times.

5. Move motion control lever to neutral position. Shutoff engine and set parking brake.

6. Engage transmission by placing freewheel control in engaged position (See "TO TRANSPORT" in this section of manual).

7. Sitting in the tractor seat, start engine. After the engine is running, move throttle control to half (1/2) speed. With motion control lever in neutral position, slowly disengage clutch/brake pedal.

8. Slowly move motion control lever forward, after the tractor moves approximately five (5) feet, slowly move motion control lever to reverse position. After the tractor moves approximately five (5) feet return

the motion control lever to the neutral position. Repeat this procedure with the motion control lever three (3) times. Your transmission is now purged and now ready for normal operation."

Should this have no results check your mower's transaxle carefully and see if yours has a filler plug on the back top side of the transmission. Most of these units should be sealed units, but some actually did have a plug. If yours does, remove the plug and measure from the edge of the plug hole down to the oil. It should measure from 1.25-1.5 inches down. If yours has more than that it would mean that the transmission oil is low. You can add 20W50 motor oil to bring it up to the right level.

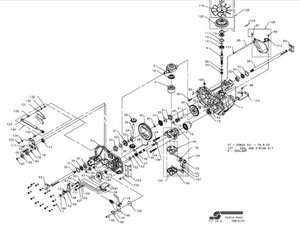

If yours does not have a plug, then we definitely would need to identify which transaxle model your mower has. See if you can find any identifying marks or tabs on the axle and let us know.

3

3  1

1

2.4k

2.4k

4 Comments

I have a manual transmission in a Craftsman GT5000 model 917 250241. I recently replaced the drive belt due to it continuesly fell off. After that I have been unable to get the shifter to change gears after engaging the 1 st shift after starting the engine. I checked the tensioner, belt config and linkage several times and they all look fine. When the engine is off it shifts smooth. Any thoughts? Thanks in advance.

by Mark Engle

Reverse not working on my 2014 Craftsman Garden Tractor. Found frame to be cracked in half on both sides. The angle changed the reverse pedal travel so it does not engage.

by ahollis57

I have a G5600 craftsman tractor and my reverse has went to almost nothing. Forward is ok but reverse is very slow to none if your trying to back on a slight incline . It has a forward and reverse peddle. Any thoughts ?

by firestorm_570

I had a similar problem with my crafstman lts2000 where it didnt reverse all i did was adjust the lever thats underneath the battery and started goin in reverse again

by Ivan Talavera