Introduction

Teardown of an Epson Stylus Photo 820 Inkjet Printer.

What you need

-

-

This is a teardown of the Epson Stylus 820 Photo color printer.

-

-

-

-

The main stepper motor, the part most likely to fail, is easy to remove.

-

The ink cartridges are easily replaceable.

-

Many parts inside the printer have ink on them, making repairs messy.

-

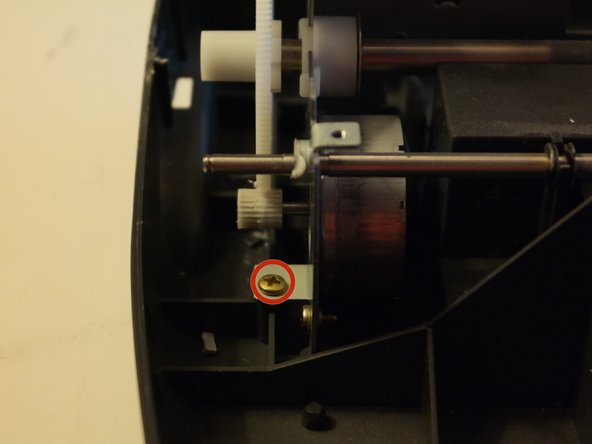

The other stepper motor is very hard to access and requires disassembling most of the printer.

-

The midframe, which contains the gearbox and secondary stepper motor, is attached to the case with blobs of melted plastic that must be cut off to remove.

-

The case is very hard and tedious to open without breaking tabs.

-

-

-

Bonus Teardown Time!

-

Time to see what is underneath the 'Do not remove' sticker located on the ink cartridge.

-

What is this network of labyrinthine passageways?

-

The answer is a capillary tunnel to reduce ink pressure. The lower row of holes leads into the cartridge itself, while the top row leads to the ink nozzles.

-

3 Comments

Thanks for sharing this blog with us.

Epson Stylus Photo R280 Ultra Hi-Definition Photo Printer is the fast, easy way to print brilliant, 4 x 6" photos or text documents.

Wavex is a US-based Coin that specializes in crypto-enabled financial services.