Introduction

Use this guide to replace the dock connector on your iPod Touch 4th generation.

WARNING: This process involves soldering.

What you need

-

-

With the heat gun set on "low", begin heating the lower portion of the Touch near the home button.

-

-

-

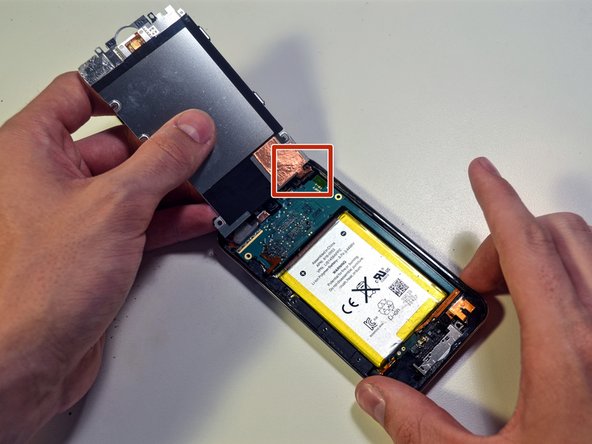

Insert the edge of a plastic opening tool under the EMI Shield near the bottom left corner of the Touch.

-

Pry upward to separate the plate from the adhesive securing it to the plastic inner case.

-

If the shield is still attached to the logic board, warm this area with a heat gun to loosen the adhesive, then separate the shield from the logic board using the opening tool.

-

There is a very thin ribbon cable here that connects the volume and power buttons to the logic board. Be careful when prying in this location as the cable is very fragile and could rip.

-

-

-

-

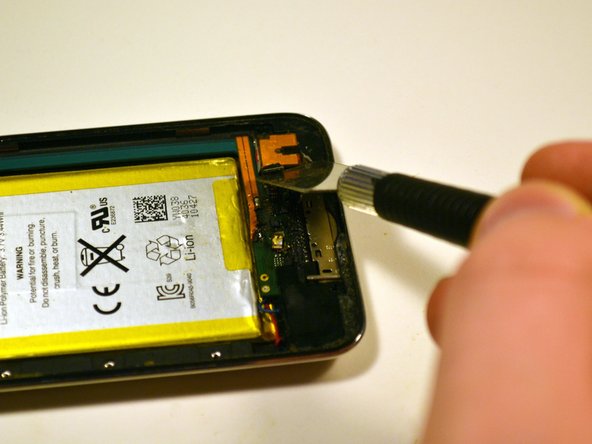

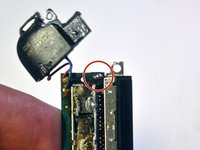

Areas highlighted in red show three solder joints to the right of the battery, along with four smaller solder joints located to the left of the battery.

-

These joints secure the power/volume flex cable (leftmost joint) and the battery flex cable (rightmost joint) to the logic board.

-

In the next few steps you will desolder the battery and power/volume flex cables from the logic board.

-

-

-

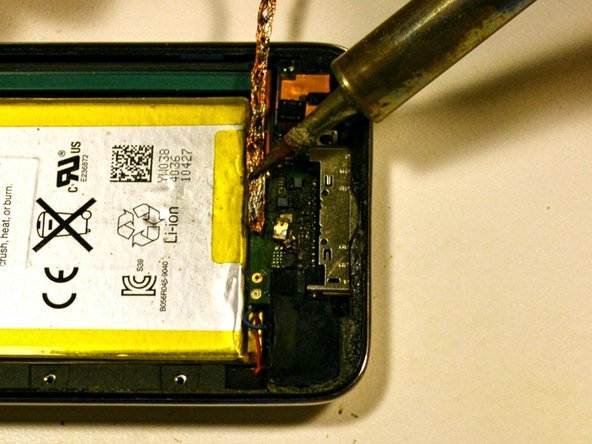

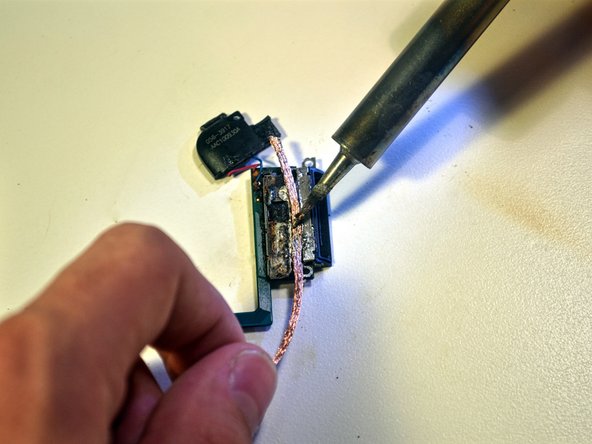

To desolder the battery flex cable, place a copper desoldering braid on top of the existing solder pads and press down on the braid with the soldering iron.

-

Once the solder melts and flows into the braid, remove the braid from the pad.

-

Repeat this process for the power/volume flex cable.

-

-

-

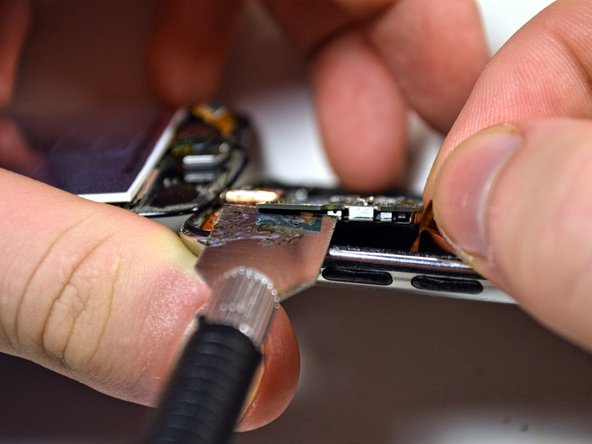

Starting above the battery near the power/volume cable attachment, use a cell phone prying tool to slowly pry the logic board straight up.

-

At this point, the top of the logic board should be lifted from the case. The bottom of the logic board and the wifi cable should still be attached to the steel housing.

-

-

-

Lightly heat the areas in red with your heat gun to soften the adhesive underneath the logic board.

-

Once heated, gently pry the logic board up with a cell phone opening tool.

-

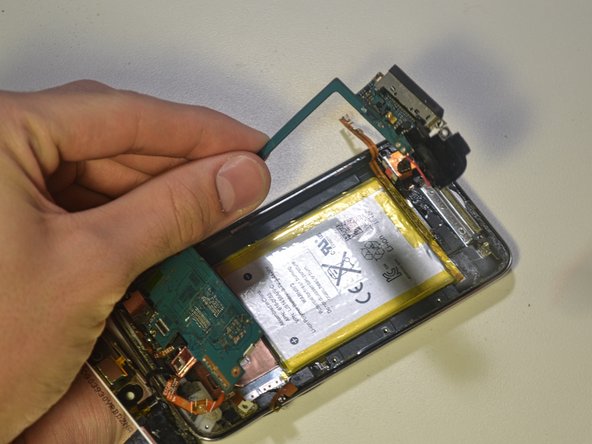

Lift the bottom of the logic board out of the casing with your fingers.

-

Remove the logic board from the steel casing.

-

-

-

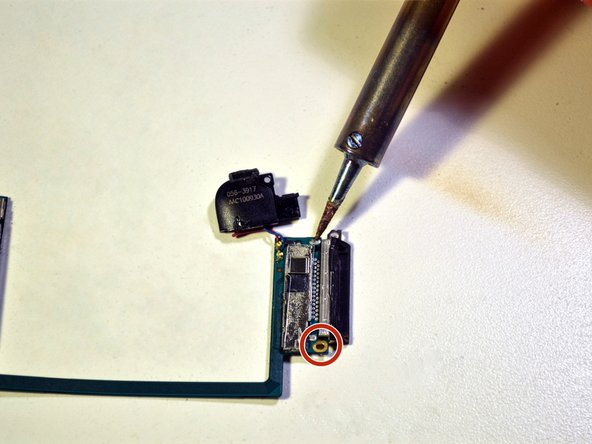

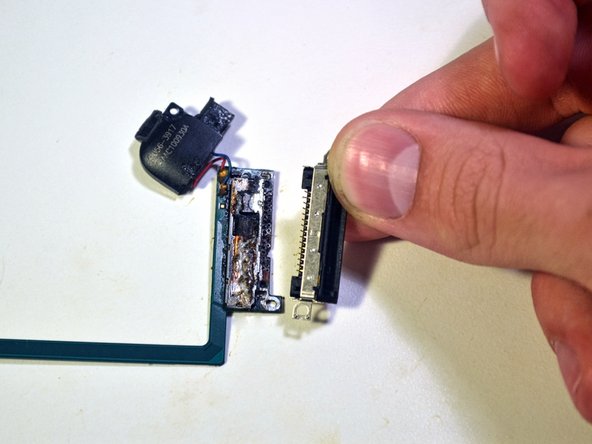

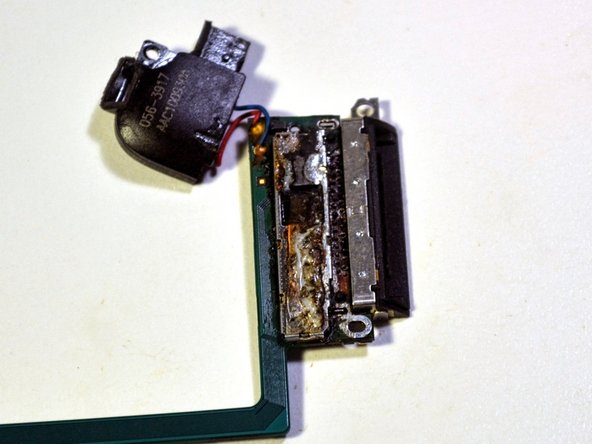

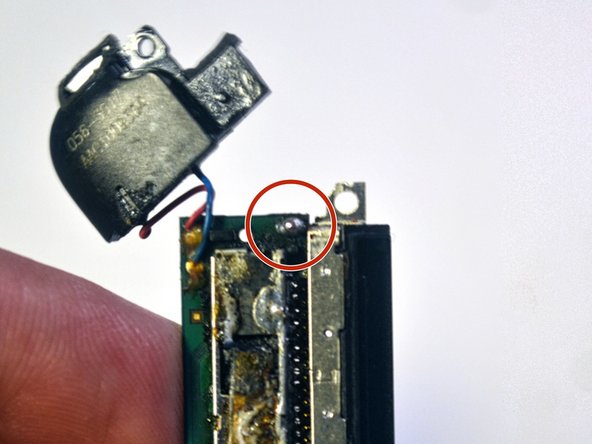

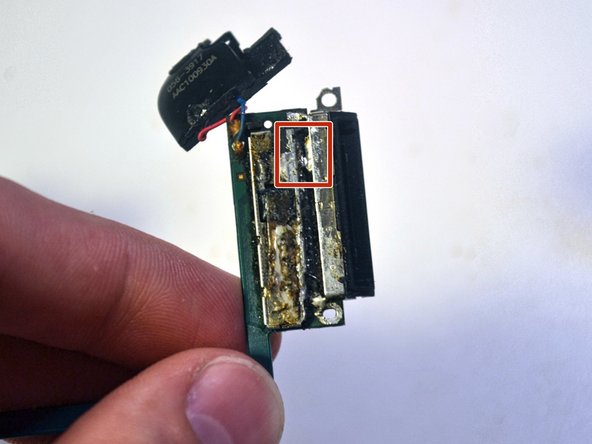

Desolder the two solder joints and the 30 pins.

-

To desolder the solder joint, place a copper desoldering braid on top of the existing solder and press down on the braid with the soldering iron.

-

Once the solder melts and flows into the braid, remove the braid from the pad.

-

Repeat this same process for the other solder joint and all 30 pins.

-

-

-

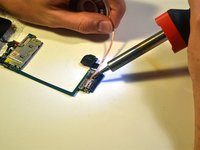

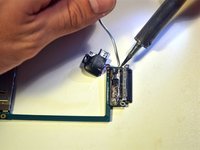

Solder the two metal joints back to the logic board.

-

Place the tip of the soldering iron against the metal joint.

-

Melt solder so that it forms a dome on top of the joint.

-

Remove both the solder and the soldering iron tip from the solder pad as soon as enough solder melts onto the pad.

-

When complete, the soldered pads should have an ovular, pill like shape.

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

12 other people completed this guide.

4 Guide Comments

How do I reconnect the "display data cable"?

If I read the instructions correctly, the "display data cable" is very short and the multi-contact connector from the iTouch screen meshes with a like connector inside the iTouch. That mesh does not appear to be very secure. Are the two connectors supposed to lock or just touch? I can't tell if contact is secure and I get no display on the screen. The battery has been replaced and, I assume, charged, but I have no way to check the voltage without disassembling the unit, once again. Aside from this problem, the top of the case (screen) doesn't lock into the bottom half. Could some sealant be preventing the locking ?

If I read the instructions correctly, the "display data cable" is very short and the multi-contact connector from the iTouch screen meshes with a like connector inside the iTouch. That mesh does not appear to be very secure. Are the two connectors supposed to lock or just touch? I can't tell if contact is secure and I get no display on the screen. The battery has been replaced and, I assume, charged, but I have no way to check the voltage without disassembling the unit, once again. Aside from this problem, the top of the case (screen) doesn't lock into the bottom half. Could some sealant be preventing the locking ?