Introduction

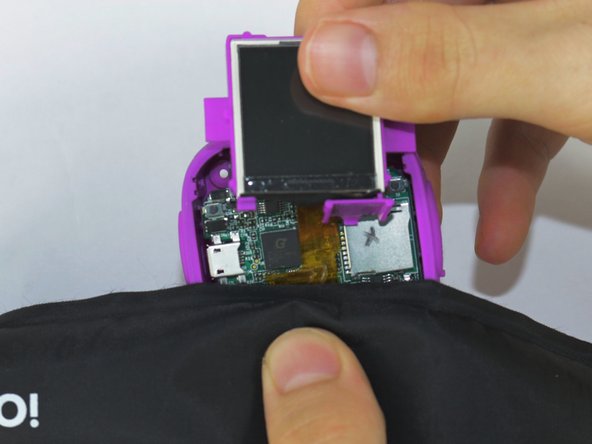

Exercise caution when lifting the LCD screen, as any excessive pulling can damage the motherboard. Otherwise, the LCD screen is one of the easiest parts of the device to replace and only requires a small amount of unscrewing, prying and gluing.

What you need

-

-

-

Heat the iOpener tool, then press the iOpener tool onto the connectors to heat the glue on the connector ribbon.

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

4 other people completed this guide.