Introduction

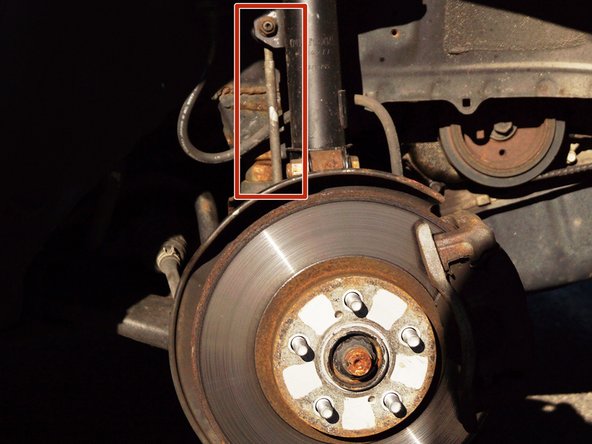

If you can hear a knocking noise coming from the suspension of your car or your car feels unstable during turns, it may be time to replace your car's sway bar links. Fortunately, replacing sway bar links is not a difficult task. Simply follow these instructions, and your car will be stable again.

What you need

-

-

Tools needed:

-

A 14mm socket wrench

-

A 4mm Allen wrench

-

Penetrating lubricant

-

A lug wrench

-

Torque wrench

-

Two new sway bar links

-

-

-

You will need to begin by jacking up the front of your car. If you need help with using a hydraulic jack, see the guide below:

-

Take the 14mm lug wrench and loosen all the bolts until they come off of the wheel and remove the wheel.

-

-

Sway Bar Links tend to wear out at a similar rates. Repeat Steps 2-13 for the driver's side Sway Bar Link.

Sway Bar Links tend to wear out at a similar rates. Repeat Steps 2-13 for the driver's side Sway Bar Link.

Cancel: I did not complete this guide.

8 other people completed this guide.

2 Comments

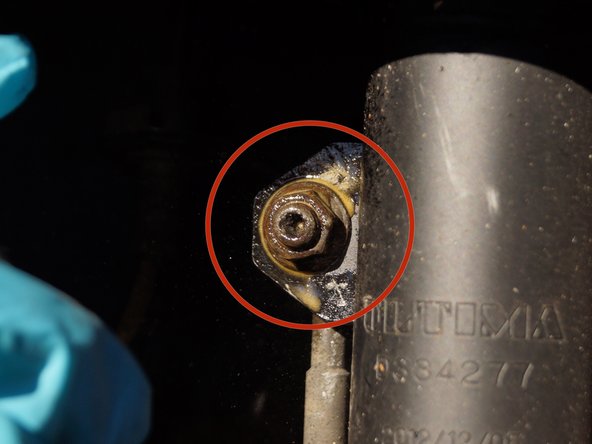

This is slightly wrong. You most likely will need a spanner and an allen key wrench to hold the bolt still while undoing the nut.

What about rear? I think my sway bar is broken. Only one link on right side other is dangling and there is nothing to attach it to