Introduction

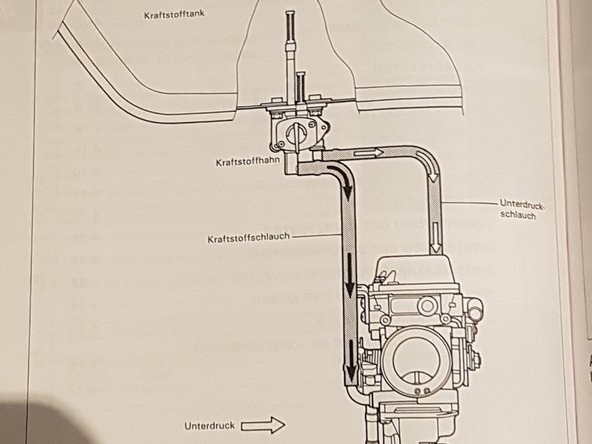

At Unterdruckbenzinhähne it can always lead to problems with the gasoline supply and leaks. That's why it should be checked and cleaned again and again. Here's a guide to the complete seal replacement on a Suzuki DR650SE SP46B. Please use original parts. (Already had problems with accessories)

What you need

-

-

The two screws, here quite funny with a large Phillips, or a 10-fork or ring spanner, unscrew.

-

Very important: The tank should be at most 1/4 full so that it does not leak. Then you can put it upright.

-

-

-

-

Re-screw the 5 Phillips screws with a suitable Phillips screwdriver (PH2).

-

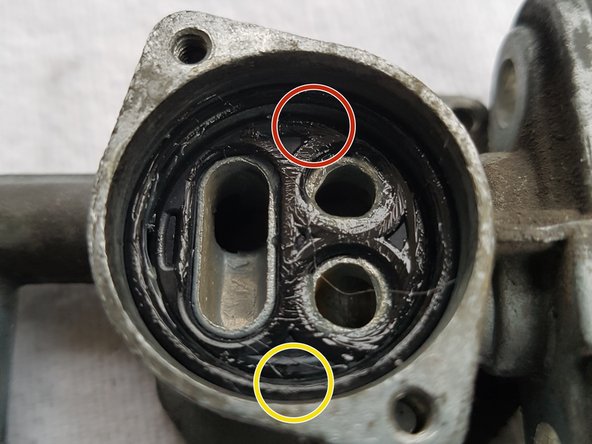

gasoline connection

-

Vacuum port

-

For functional testing, you must now apply a slight vacuum to the vacuum connection, which causes the cap to open. This can then be tested by blowing at the gasoline connection. When the vacuum drops, the shutter must close immediately.

-

Now install the foot gasket.

-

Special thanks to these translators:

100%

irlanda is helping us fix the world! Want to contribute?

Start translating ›