Introduction

The motor is a big part of having the turntable turn, because it spins the drive belt. Replacing it requires some specialty work such as soldering, because it has some electrical components that need to be connected to a power source. Other than that, everything is pretty simple in replacing the motor.

What you need

-

-

-

Lift the rubber mat, and put it to the side. It should be easy to remove, because it simply rests on a metal platter without anything securing it down.

-

-

-

Use a PH2 screwdriver to remove the 8 screws from the bottom cover.

-

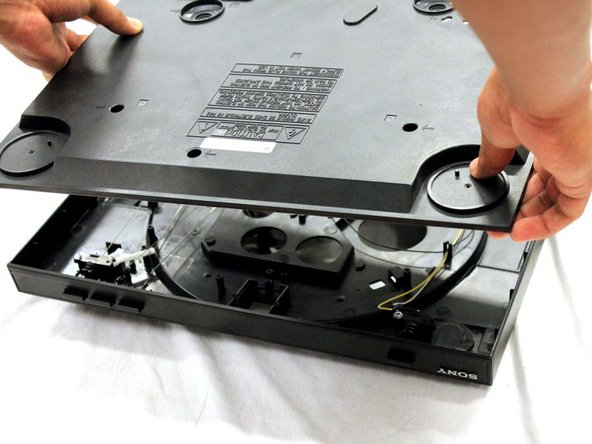

Now lift the bottom cover to remove it.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.