What you need

-

-

Remove all the following screws:

-

Red M2.5×6 (16 pieces)

-

青 M2×5 (2本)

-

-

-

Remove the warning label and S/N label.

-

Remove the bottom exterior

-

-

-

Remove all screws that secure the airtight module to the housing

-

Red M2.5×12 (8 pieces)

-

Blue M2 x 5 (4 pieces)

-

-

-

Remove all screws from the airtight module

-

M2.5x8 (48 pieces)

-

-

-

Remove all the screws that attach the camera module

-

M2x5 (8 Pieces)

-

-

-

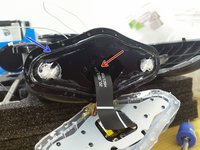

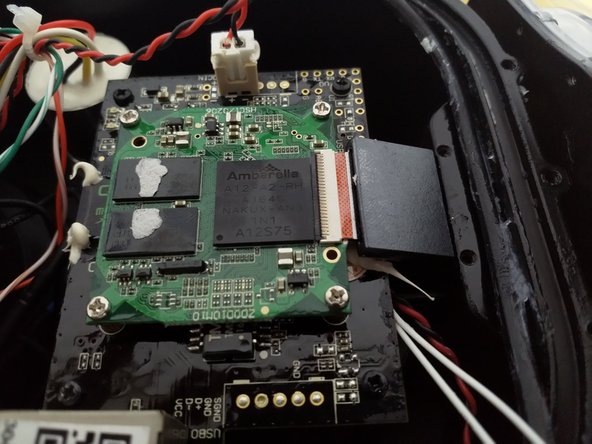

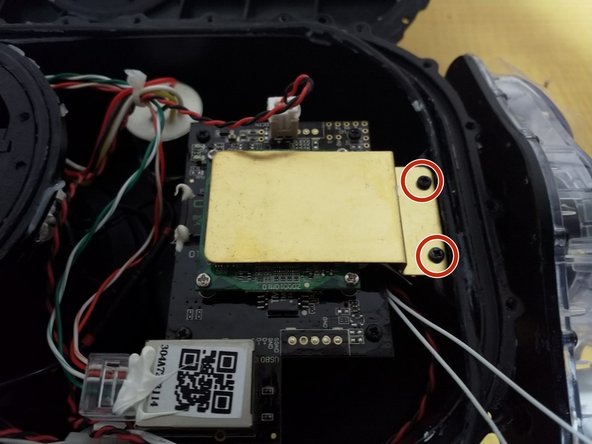

Remove the screws circled in red. M2×5 (2 pieces)

-

Remove the heatsink indicated by the orange arrow.

-

-

-

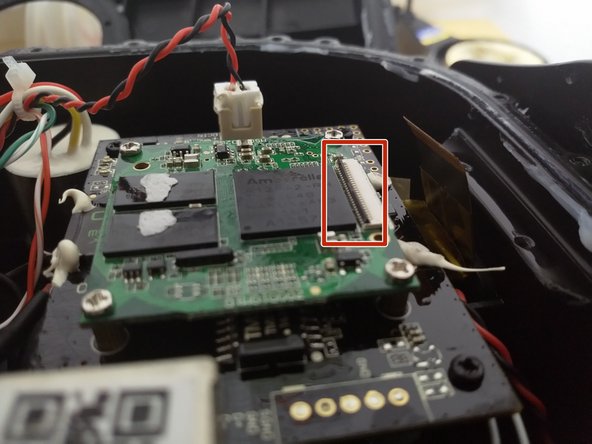

Unlock the flexible cable connector (raise the black lock)

-

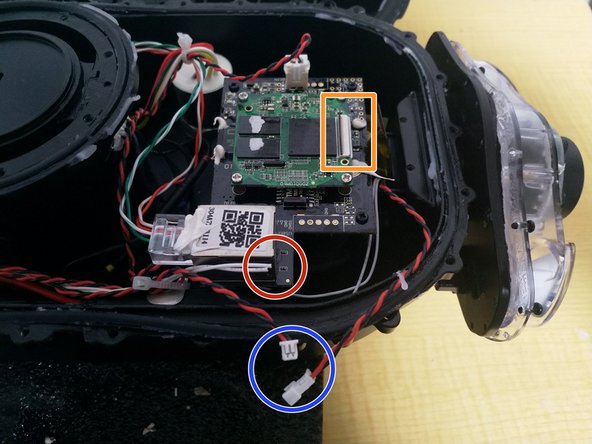

The ferrite core indicated by the orange arrow will be reused, so keep it.

-

-

-

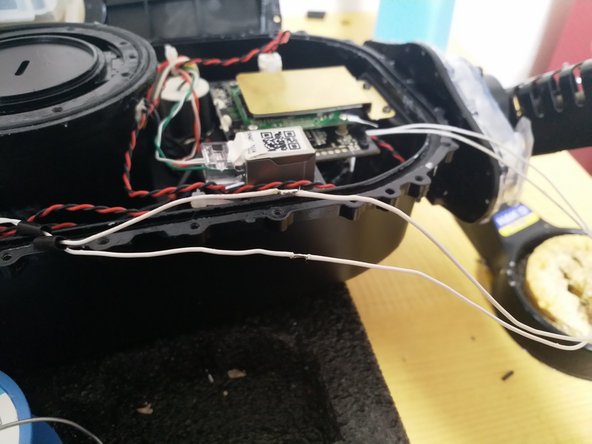

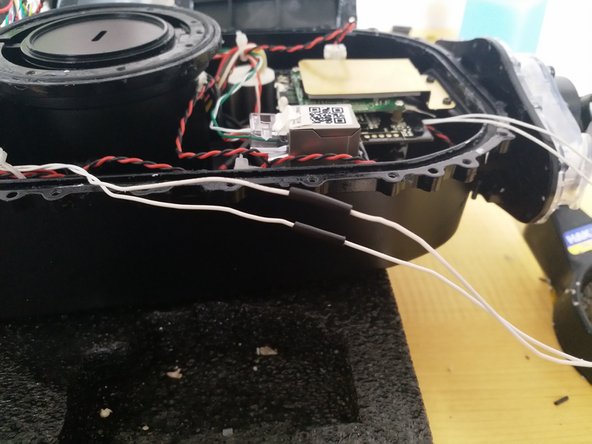

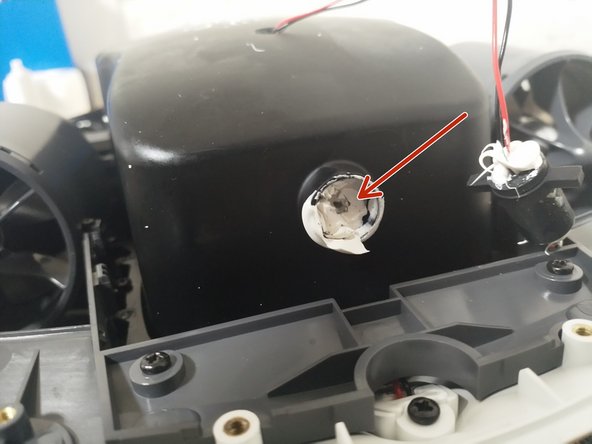

Cut the white magnet cable (red circle position)

-

Remove the LED connector (blue circle position)

-

After confirming that the flexible cable, magnet cable, and LED cable have been removed, pull out the camera module.

-

-

-

-

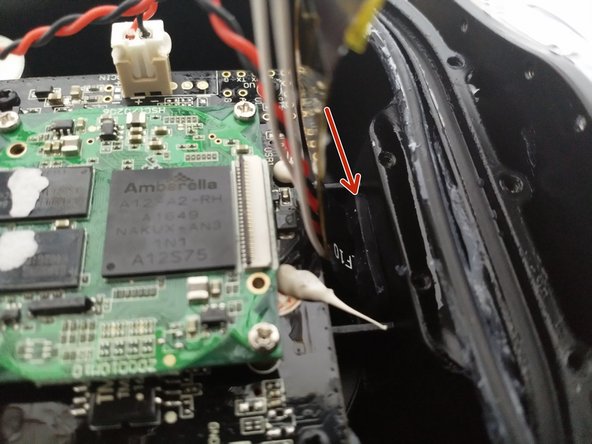

Insert the camera cable into the main unit from the arrow position (flexible cable, magnet cable, LED cable)

-

Check that the O-ring is not scratched, cut, or damaged, apply grease to it and fit it firmly into the groove.

-

-

-

Attach the camera module to the mount

-

Tighten diagonally a little at a time, tightening to a torque of 4.9 [cN・m].

-

Finally, tighten it one more time at 4.9 [cN・m]

-

-

-

Insert the ferrite core that you removed earlier.

-

Remove the Kapton tape from the end of the cable.

-

Install the flexible cable

-

-

-

Replace the double-sided tape on the back of the heat sink

-

Remove the release paper from the double-sided tape and secure it with M2 x 5 (2 pieces).

-

-

-

Peel off the coating of the magnetic cable on the main unit and insert the shrink tube.

-

Solder the cable on the main unit and the cable on the camera.

-

Fix the shrink tube with a heat gun

-

-

-

The LED lights up just like in the picture.

-

Startup sound is normal

-

All motors and cameras are functioning normally.

-

-

-

Check that both O-rings are free of scratches, damage, and dirt, and apply grease to them and align them with the grooves.

-

Close the upper module, being careful not to catch any cables or debris.

-

-

-

Place the plate on and tighten all 48 screws

-

M2.5 x 8 (48 pieces)

-

Tightening torque = 39 [cN・m]

-

-

-

Install the M2.5 x 12 (8) screws.

-

Insert translation here

-

-

-

Remove the silicone sealant

-

Remove the airtight bolt with a 3mm hexagonal wrench

-

-

-

Install the airtight test bolt in the place where the airtight bolt was removed.

-

Attach the hose and pump to the airtight test bolt

-

Pressurize to 140kPa, submerge in water, and check for no leaks for 3 minutes.

-

-

-

Remove the airtight test bolt

-

Wrap the O-ring and sealing tape around the airtight bolt that you just removed and install it.

-

-

-

Attach the four exterior parts

-

Attach the safety seal and S/N seal

-

Special thanks to these translators:

100%

BTL Repair AU is helping us fix the world! Want to contribute?

Start translating ›