Introduction

Almost all gas now contains up to 10% ethanol. Ethanol is one of the leading causes of damage to small gas engines. The alcohol can cause corrosion on rubber and plastic parts and can make gas powered yard tools almost impossible to start. I will illustrate how to replace the parts that are most common to fail,the primer bulb and fuel lines. While disassembled I will also illustrate how to replace the fuel filter and air filter of the Poulan P3314 2-Cycle Chainsaw.

What you need

-

-

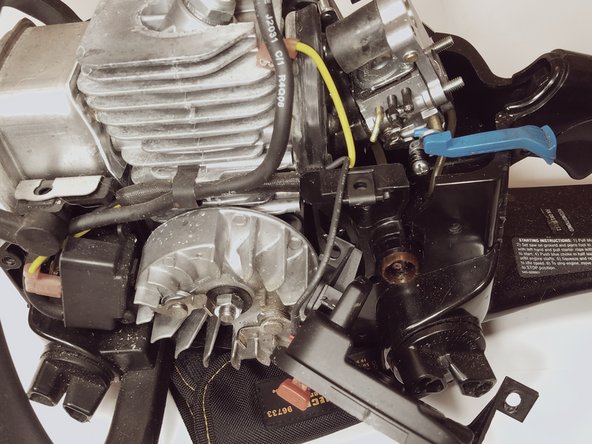

Unscrew the three T25 screws on the top cover.

-

Remove the top cover and set aside.

-

-

-

-

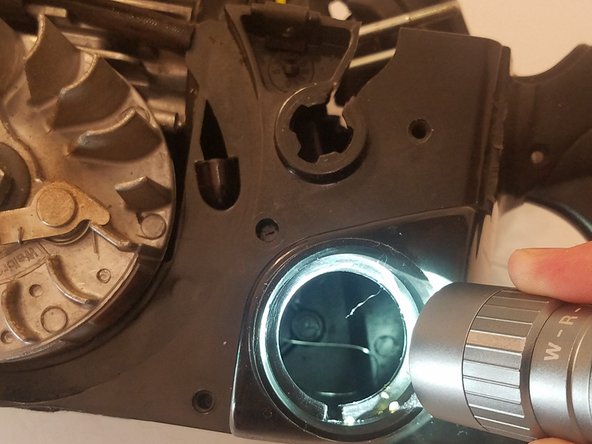

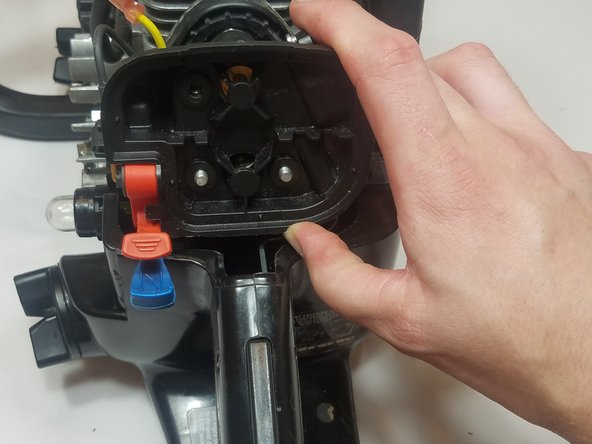

Using a flat head screwdriver or spudger to press the tabs on the inside of the primer bulb assembly. (This will release the primer bulb from the housing).

-

Pull the damaged primer bulb out of the engine housing.

-

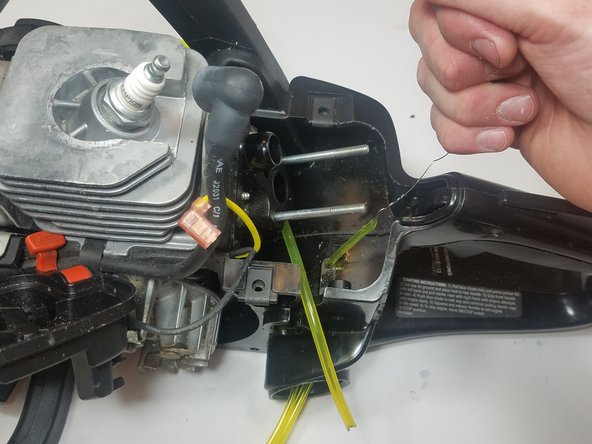

Use long needle nosed pliers to disconnect the two fuel lines from the primer bulb.

-

-

-

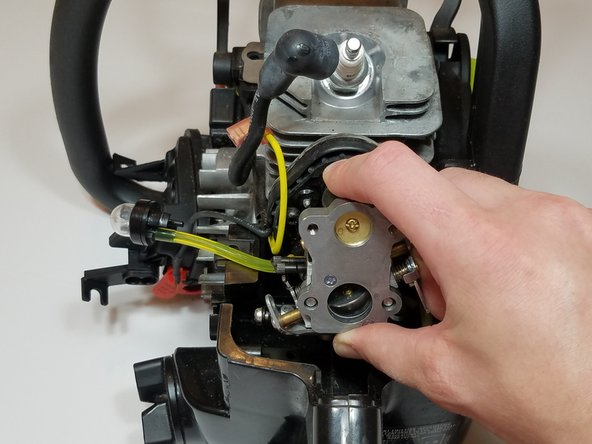

If the primer suction line was damaged, slide the carburetor back onto the mounting bolts.

-

Attach one end of the new fuel line to the incoming fuel port on the carburetor.

-

Move the fuel line through the primer bulb housing and hold the primer bulb up to the fuel line.

-

Mark desired length and cut to size.

-

-

-

Attach the larger diameter fuel line (fuel filter line) to the intake inlet on the carburetor.

-

Attach the smaller diameter fuel line (fuel return line) to the return port on the primer bulb (longer nipple).

-

Slide the carburetor back onto the mounting bolts while pulling out the slack out of the fuel lines from the gas tank.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

38 other people completed this guide.

20 Comments

Any idea where I downloaded shop manuals for small engin repairs looking for stihl 039 manual

Yes I would try manuals.lib at the Google play store.

Daniel. Here you go. Hope this works out for you.

Excellent instructions

Thank You

How do you choose the best choose the best product among the ones listed here? <a href="https://onlychainsaw.com/best-scroll-saw... ">https://onlychainsaw.com/best-scroll-saw... </a>