Introduction

If your camera lens and lens motor has been broken, this guide will show you step by step how to replace the broken lens and motor with a new ones.

What you need

-

-

There are six screws attaching the back housing to the camera. Remove the screws from the body with a PH000 screw head.

-

Two 1.5x2.5mm screws on the right side.

-

Two 1.5x2.5mm screws on the underside.

-

Two 1.5x2.5mm screw on the left side.

-

-

-

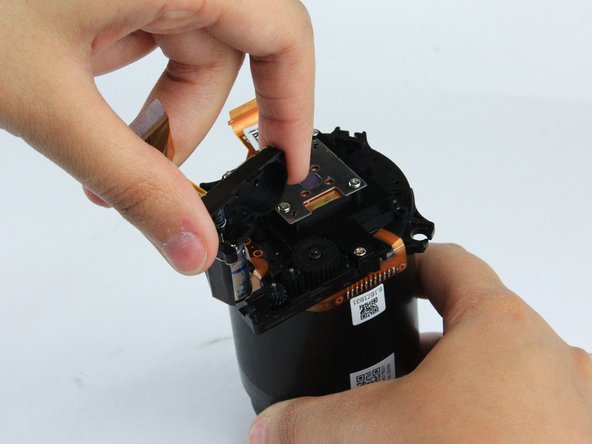

Insert the tips of your fingers into the space between the screen and back-plate.

-

Gently lift the screen up and out of the frame.

-

-

-

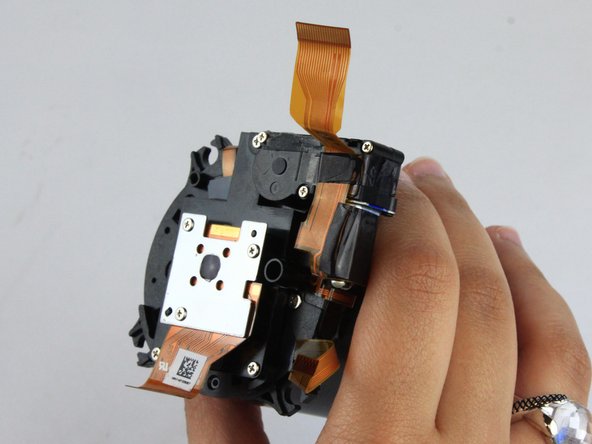

Remove the screws from the silver back-plate with a PH000 screw head.

-

Two 1.5x2.5mm screws on the left side.

-

One 1.5x2.5mm screw on the right side.

-

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

One other person completed this guide.