Introduction

This guide will show you how to take the tool apart all the way down to the gears so that you can replace the reduction gear assembly. The reduction gear assembly can fail due to wear and tear. If you are experience grinding or slipping issues in the gearbox of your rotary hammer, the cause may be due to a faulty reduction gear assembly.

What you need

-

-

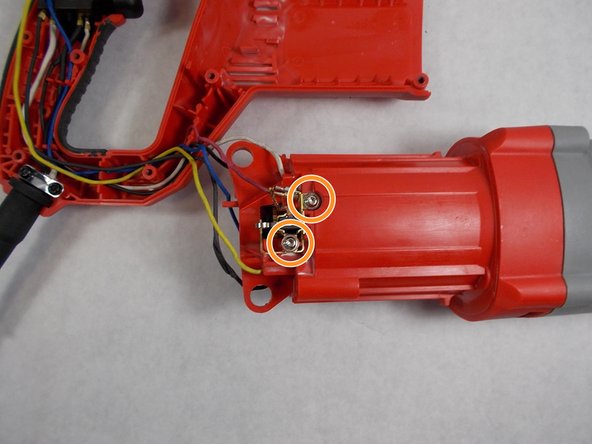

Remove the two 10mm T-10 Torx screws that attach the top brush holders to the motor housing.

-

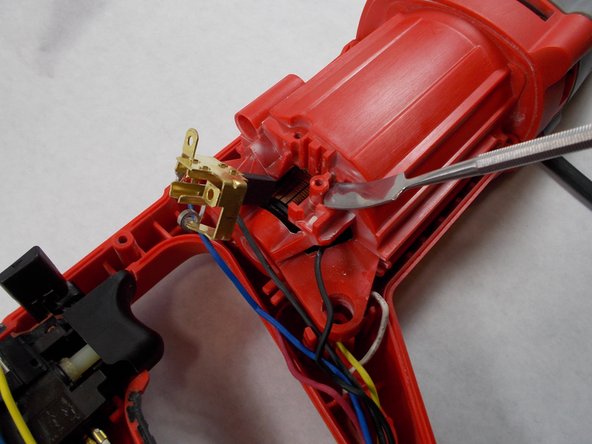

Remove the two 10mm T-10 Torx screws that attach the bottom brush holders to the motor housing.

-

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

One other person completed this guide.