Introduction

If your Logitech G27 will not respond properly, even after calibrating, you may need to replace its optical encoder. The optical encoder is a small electronic device that turns the wheel's rotation into an electronic signal for the computer to understand. It isn't too hard to replace, you just need plenty of patience because you'll be taking out a lot of screws! Make sure your wheel is completely unplugged before starting this replacement.

What you need

-

-

Remove the six gray 25mm hex screws with a 4mm allen wrench.

-

Carefully lift up the wheel, but do not disconnect it from the rest of the device.

-

-

-

-

After following the prerequisite guide, invert your device.

-

Remove the four center-most screws from the bottom of the device with a Phillips #1 screwdriver.

-

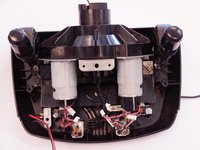

Invert your device back to its original position, and completely remove the motor housing from the rest of the device.

-

-

-

During reinstallation make sure when doing this step to align the stop on the wheel gear with the track as shown in the second and third pictures.

-

Also make sure that the metal half-circle clip is placed properly inside the slot.

-

After placing the metal clip in the slot, place the plastic cog on top of the clip and on the rail.

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

51 other people completed this guide.

35 Guide Comments

If your wheel doesn't calibrate.Then check your optical encoder. It's 90 percent of the issue You can find replacement in the ETSY with the buyer name " abrapartabra " for logitech optical encoder 30 or 60 slot they have for Logitech G25 , G27 and DFGT . They have been made like original, but with more reliable plastic. We fixed our Logitech steering wheel

Hello and thanks for the guide. I understand this might be off topic, but would you happen to know the pinout of the7-pin connector in step 5? There is no label on the pins. Thanks in advance for your time.

Are you sure about Step 19 alignment. Some other guy with G25 says it has to be dead centre alligned otherwise you get blinking lights.And that's exactly what happens to me.