Introduction

This guide will pick up from the pre requisite guide Disassembling Logitech G27 Steering Wheel. In this guide we will be showing how to replace the motors that create force feedback in-game. After following this guide your Logitech G27 Steering Wheel should be fully functional.

What you need

-

-

Remove the six gray 25mm hex screws with a 4mm allen wrench.

-

Carefully lift up the wheel, but do not disconnect it from the rest of the device.

-

-

-

-

Remove the four 12.2mm screws using the Phillips screw driver.

-

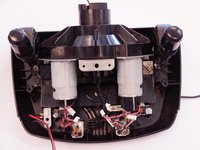

The motors and gear box should now slide out. As you take it out, the metal spring band as well as the track for the wheel gear will also slide off.

-

When you have separated these parts, you can set them aside until reassembly.

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

19 other people completed this guide.

7 Guide Comments

If you do not feel confident doing this yourself, here is a link to a company that could do it for you http://www.mz-simulators.co.uk/services....

Where can i buy this motors ?

i found 1 of each

going to buy the encoder as well and start with it and then motors if needed