Introduction

There may come a time when the cord or power adapter will fail, either through general use or lifetime failure.

This may require cutting and soldering, so be prepared to potentially void your warranty.

This may also be used for other devices, as the principal is the same.

What you need

-

-

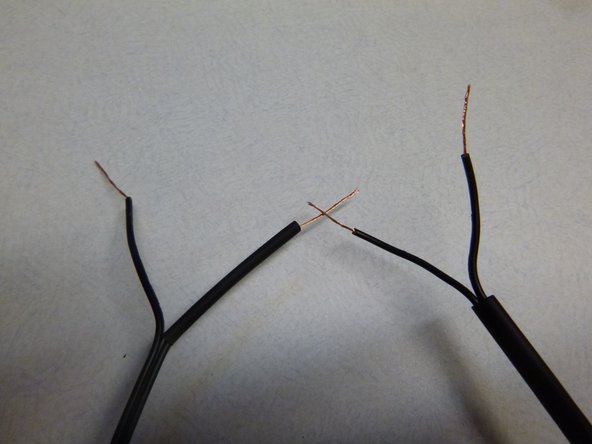

Take note of the wire labeling. Each wire has either a Stripe or Text. When lining up the wires after cutting, it is critical that you keep Stripe with Stripe, and Text with Text. Failure to do so will result in damage to the device.

-

-

-

-

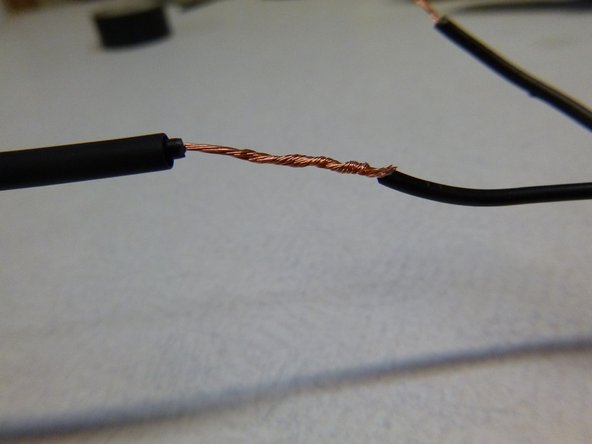

Pull the wire seperation back far enough on at least one side to permit Heat-Shrink to slip over the wire insulation.

-

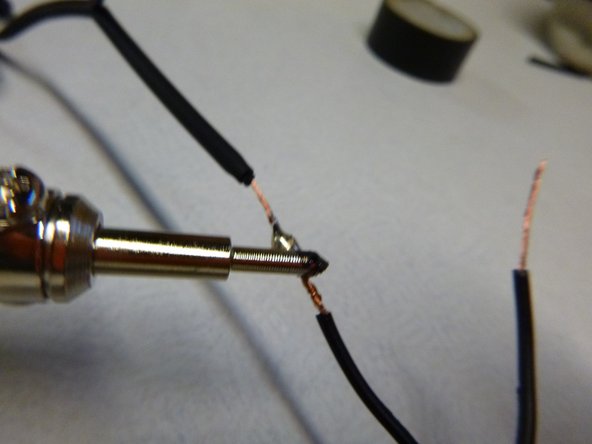

Now the soldering. Place the pre-heated iron on the wires on a heat-resistant, flame proof surface. Make sure that the Heat-Shrink is nowhere near the soldering iron.

-

Let it heat for a few sconds (copper is an excellent conductor of heat), then touch the end of the solder to the wire. If fully heated, it should flow easily into the joint.

-

To reassemble your device, follow these instructions in reverse order.