Introduction

Disassemble the gear to replace the "Vertical Drive Shaft" and the "Planet Hub"

What you need

-

-

Loosen hex nut

-

Pull "Planetary Hub" straight away

-

Loosen Torx screws holding the lower housing

-

-

-

Take away lower housing

-

Rubber can be taken away for cleaning

-

Take away damping lint

-

-

-

Unscrew to take away the plastic parts

-

The parts are different

-

The screws have no metric thread

-

-

-

Unscrew the 3 Torx

-

Lift off the Upper Housing

-

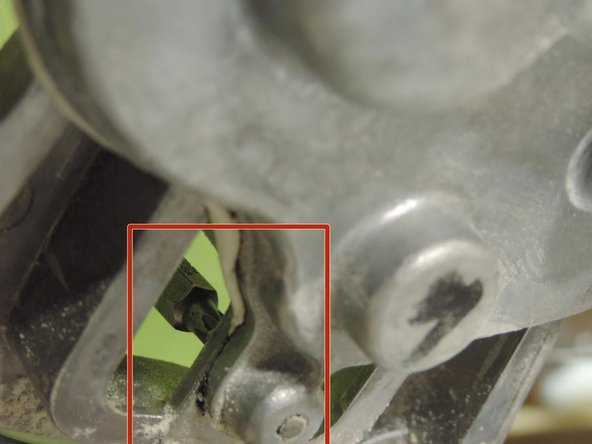

Take care of white rubber marked with the red square

-

-

-

-

No need to proceed with the custom tool if the plastic wheel has already been removed in the previous step

-

The tricky part is to unscrew the Tx20 screw located under the plastic wheel

-

I was not able to pull the plastic wheel from the shaft

-

If you like the risk you might drill a hole in the plastic wheel for easy access

-

I used a custom tool -> see next step

-

-

-

I machined a 6 mm wrench to fit on the Tx20 bit

-

After removal I slotted the screw for easier mounting

-

-

-

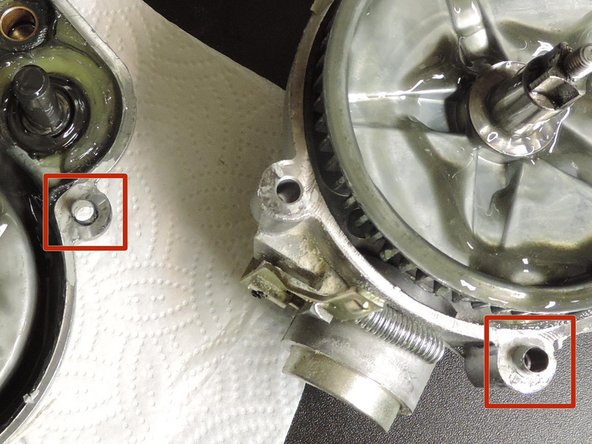

Take care of the guides (red markers). They can be pushed in after closing the gear box

-

Take away the sealing. To reseal I used sealant normally used in washing rooms.

-

-

-

The one with the cross is the old one

-

The bayonet doesn't look the same but the tools fits as before. The position of beater and whisk stay the same in respect to the bowl

-

The thickness change of the gearwheel doesn't seem to matter

-

-

-

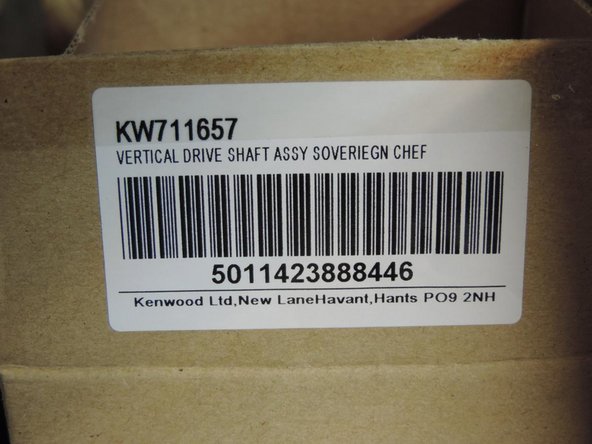

Cod. SER1018: Label of the bag containing the tree parts

-

Label of "Planet Hub"

-

Label and part designated "Planet Hub Nut"

-

-

-

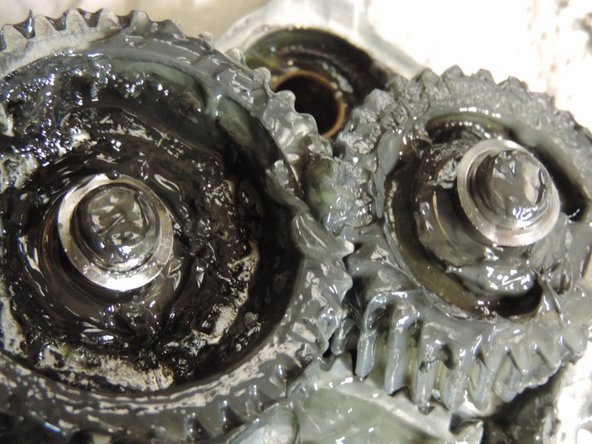

There is plenty of grease. Put it on the parts to be greased.

-

Put sealant on the box (see step 8)

-

Place the machine upright standing in the normal working position with lowered arm. The front axle will fall out if the arm is in the upper position.

-

Gently slip the lower part in the upper part

-

As the screws were loose when disassembling, I put a drop of thread locker before mounting.

-

Mount the guides in the correct place

-

To reassemble your device, follow these instructions in reverse order at step 6.

To reassemble your device, follow these instructions in reverse order at step 6.

Cancel: I did not complete this guide.

5 other people completed this guide.

14 Comments

Hello,

I was not able to realise the suggestion of "Jens" in step 6. Maybe it works on older machines (A901), but it did not work on my Chef Titanium KM001 which has the same gear as the one depicted herein. I chose to make a hole in the plastic wheel instead, using a Dremel at with a corundum tip, after marking the right distance from the center with a pe n by applying the pen from below at the same distance as the screw and rotating the plastic wheel. The The TX 20 screw came off just fine and without fiddling around. The machine turns again. Note: I had not put enough grease inside, and it didn't sound so good. I therefore added additional lube via the hole under the red stopper, and everything was fine (no need to disassemble the machine again).

It worked for me. The YouTube video was very useful to see how to get the plastic wheel off. My only problem is that on reassembly I found a black rubber seal (I think it’s a seal) but I couldn’t see where it belongs. Its tapered. If anyone has a suggestion, I would appreciate it.

Hallo,

zuerst mein Kompliment zur gelungenen Darstellung. Meine Kenwood KM001 Chef hat noch den Kreuzantrieb. Die Fotos 1-3 zeigen den Antrieb mit Bajonetanschluss. Bei meiner KM001 ist lediglich der Anschluss am Plantengetriebe zum Knethaken verschlissen.

Daher meine Frage: findet dieser abgebildete Austausch des kompletten Kenwood Chef Planetengetriebes SER1018 statt, weil es das komplette Getriebe defekt ist? Kann es sein, dass es das Kreuzgetriebe nicht mehr mehr als Ersatzteil gibt oder ist das neue Teil mit Bajonetverschluss kompatibel auf den Kreuzantreib der Antriebsachse?

Vielen Dank für eine Erläuterung

Harald.K.

Hall Bruno,

Keine Ahnung, ob mein Kommentar von gestern angekommen ist. Vielen Dank für die detaillierte Anleitung. Sie hat mir sehr geholfen. Obwohl das Video nicht funktioniert ist es mir problemlos gelungen das Kunststoffzahnrad gegen den Uhrzeigersinn zu lösen. Bei mir ist der untere Getriebedeckel gebrochen. Es gibt verschiedene , aber entweder in Italien oder UK, oder “ nicht auf Lager" . Hast du noch einen Tipp?

Beste Grüsse

Armin