Introduction

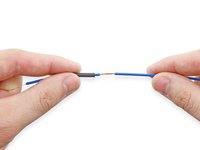

Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable.

What you need

-

-

Measure the diameter of the wire, and then choose a piece of heat shrink that will be large enough to slide onto the wire before heating but will still provide a snug fit once heated. The shrunken diameter should be slightly smaller than the wire's diameter to ensure a tight fit.

-

-

Cancel: I did not complete this guide.

35 other people completed this guide.

7 Guide Comments

I find that using a rectangular, one-sided razor blade instead of scissors makes for straighter/cleaner ends, especially vs. larger diameter tubing.

Some alternate heat sources for heat-shrink tubing:

* Soldering iron. Hold the iron close to, but not touching the wrap. You may have to apply heat to multiple sides of the wrap, as the convection may not evenly reach all sides of the wrap.

* Cigarette lighter or candle flame. Not a great solution, but works if no better sources are available. If you let the flame touch the wrap, you can end up with soot depsoited on it. Soot will wipe off easily, but it is easy to burn the wrap and wire, even setting the insulation on fire, if you are careless and let the flame sit too long in one spot or for too long.

I want to repair a wire but it is attached to a hefty plug one end, and adapter at the other, and the heat shrink I’ve got won’t fit over these. Any suggestions?

You would be better off using electrical tape, Heat Shrink is designed to be used on new connections such as 2 wires soldered together and has to be slid on before connecting the wires together or before a larger end connector is attached , it also needs to be the correct size for the wire being covered since it will only shrink to 2 or 3 times its original size,

In your case you would have to cut the cable, slip on the heat shrink and then solder the wires back together before using the heat shrink to cover the bare wires or you could just use a shielded connector designed to connect cables together and forget the heat shrink