Introduction

The voltage regulator's purpose is to monitor the battery voltage, in which it will maintain a predetermined charging system voltage level. The regulator also controls the current flow to the rotor assembly.

The regulator will increase the field current, (there by strengthening the magnetic field) when the charging system voltage falls below this point, which increases the alternator's output. However, when the charging system voltage rises above this point, the regulator will decrease field current , which weakens the magnetic field, and decreases the alternator's output.

What you need

-

-

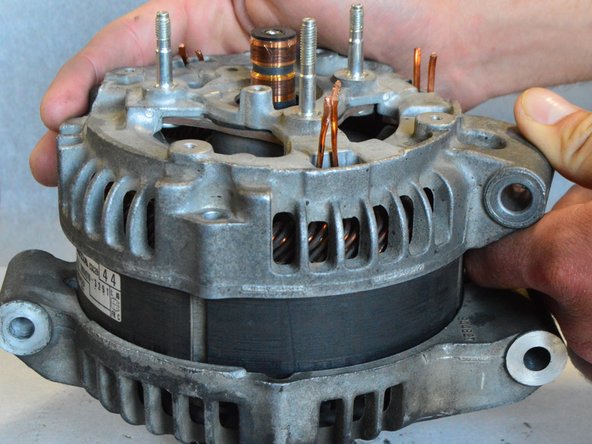

With the alternator cover removed, use a #2 Phillips screwdriver to remove the two, 6 mm screws that hold the brush cover in place.

-

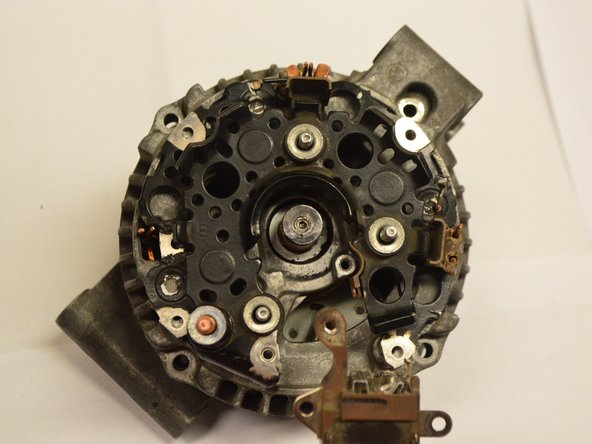

Remove the brush cover assembly from the alternator. You might need to insert a needle in the small hole to separate the brushes from the rotor. Pull it out without using much force to avoid damage.

-

-

-

-

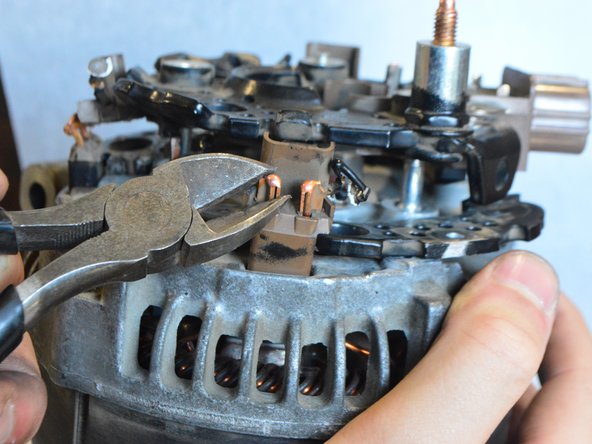

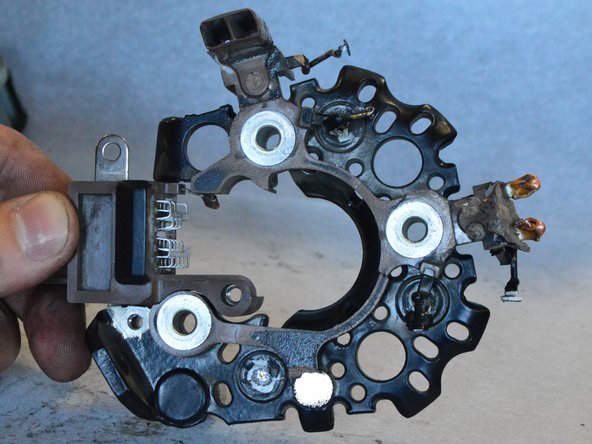

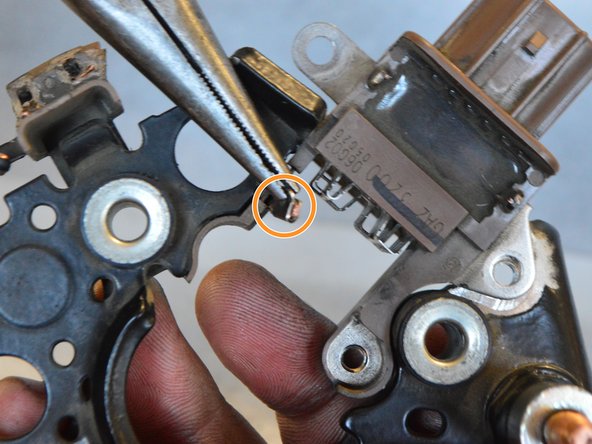

Locate the small metal clasp attaching the voltage regulator to the the rectifier.

-

Loosen the clasp using a pair of needle-nose pliers

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

6 other people completed this guide.