Introduction

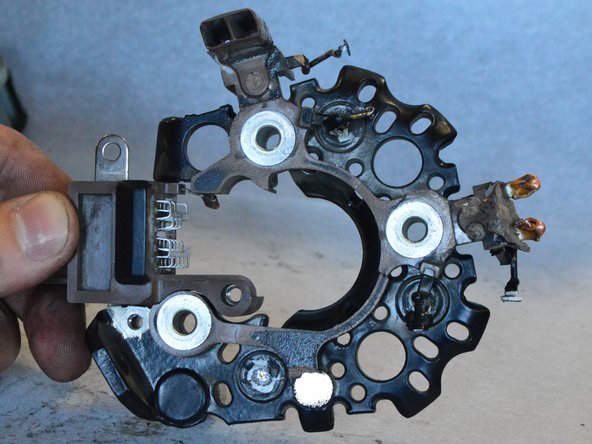

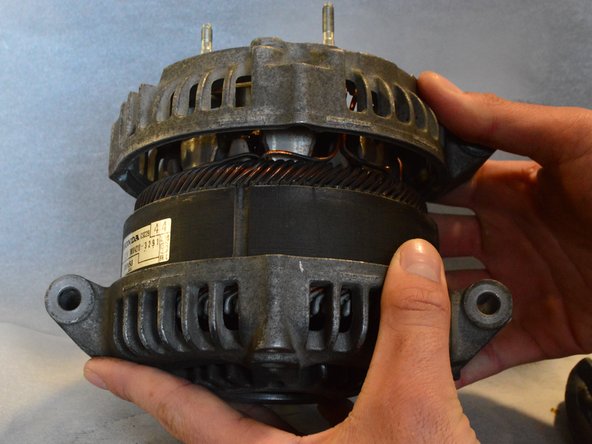

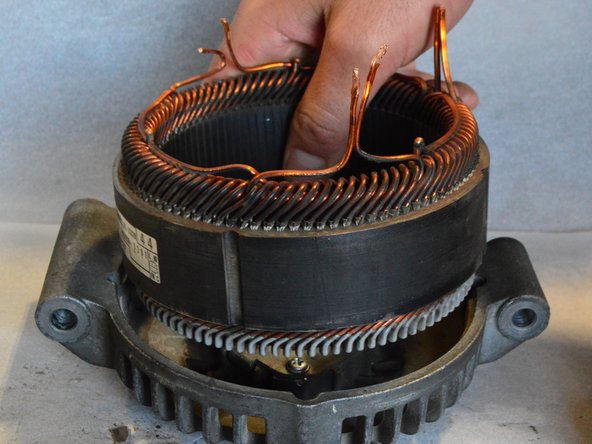

The objective of this repair guide is to instruct the reader how to remove and replace the stator in the CSC29 alternator. The stator is a series of copper windings that transfer current generated from the rapidly rotating rotor to the rectifier bridge assembly. This current eventually finds its way back into the car battery.

What you need

-

-

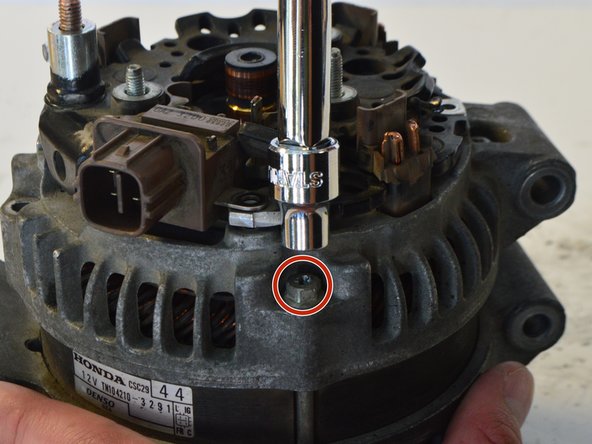

With the alternator cover removed, use a #2 Phillips screwdriver to remove the two, 6 mm screws that hold the brush cover in place.

-

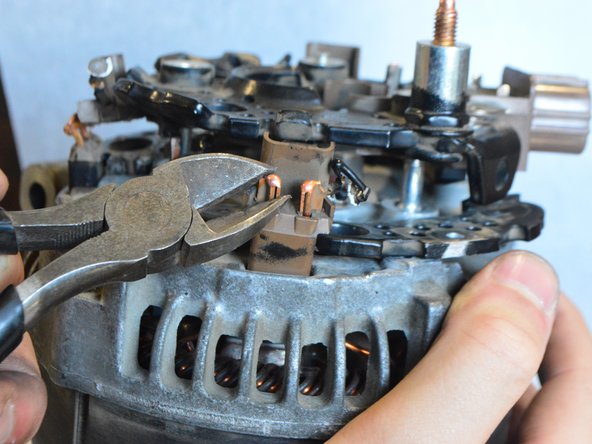

Remove the brush cover assembly from the alternator. You might need to insert a needle in the small hole to separate the brushes from the rotor. Pull it out without using much force to avoid damage.

-

-

-

-

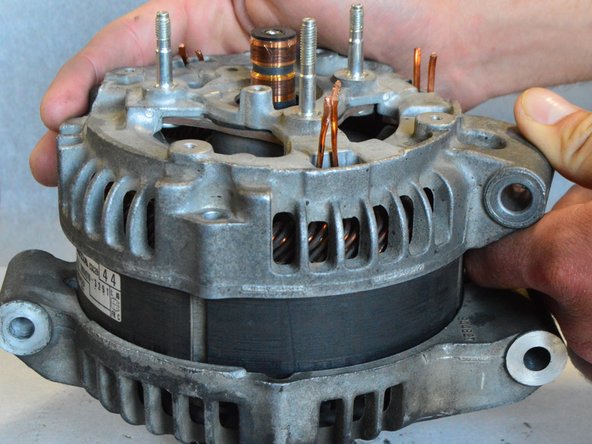

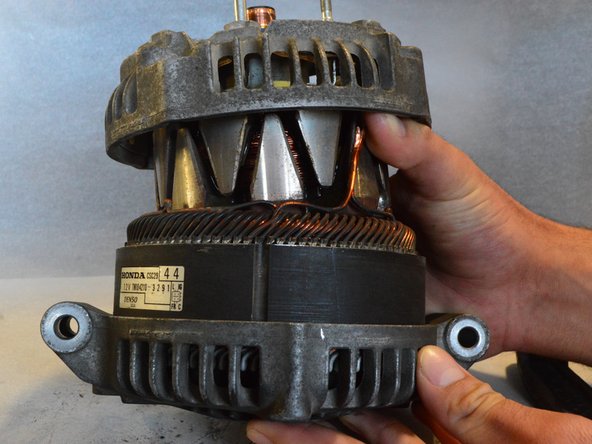

Use a Philips #2 Screwdriver or a 7.5mm socket driver to unscrew the 4, 7.5mm bolts running along the outer perimeter of the alternator

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

5 other people completed this guide.