Introduction

Older Dell monitors are prone to blowing capacitors. If the power button flashes and the screen refuses to turn on, then your monitor has likely blown a capacitor.

This guide will show you how to disassemble the monitor, locate the capacitors, and replace any that may have blown. Before attempting to follow this guide, ensure the monitor is completely disconnected and that you are aware of the dangers of capacitors. Soldering experience would be helpful.

What you need

-

-

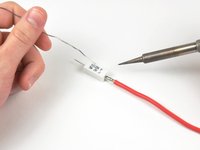

To construct a capacitor discharge tool, first gather the necessary materials. These include:

-

Two lengths of wire. Minimum wire requirements is 12AWG, 600 volt rating for large electrolytic capacitors used in power supplies, electric motor start circuits and camera flash circuitry

-

A resistor rated to dissipate the amount of thermal energy created when discharging the capacitor. Minimum requirements for resistor is 2k OHM 5w for small capacitors, 20k OHM 5w for large electrolytic capacitors used in power supplies, electric motor start circuits and camera flash circuitry.

-

Shrink tubing

-

-

-

-

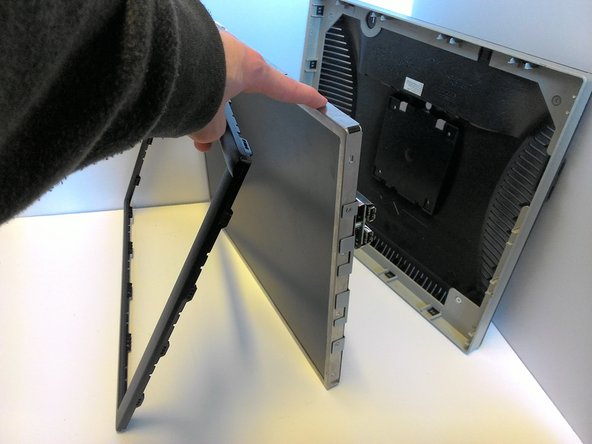

Before replacing the capacitors, open the monitor and find the power board. First, remove the monitor from the stand.

-

The button to remove the stand is located on the back of the monitor, above the ports.

-

-

-

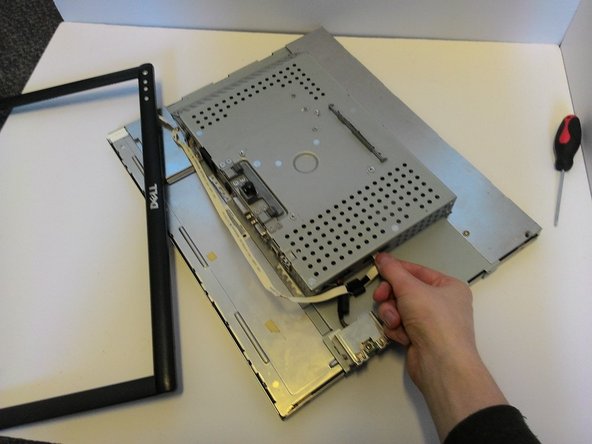

Flip the monitor around and locate the two slots on the edges. These slots are below the screen where the faceplate is attached.

-

Use a flat tool (such as a flathead screwdriver) to pop the front frame off. It is attached via plastic snaplocks and will come off with some prying.

-

Once the faceplate is removed, the monitor can be removed from the housing, leaving the monitor and the faceplate attached with a ribbon wire. The wire can now be pulled from the slot, fully removing the faceplate from the monitor.

-

-

-

Remove the plates protecting the wires. There are a total of 5 screws holding two plates onto the top and bottom.

-

With the plates removed, we can now unplug the 2 green and 2 pink wires connecting the electronics to the screen. This is best done with needle nose pliers, since the attaching head must be depressed and pulled at the same time.

-

-

-

After all the capacitors are safely discharged, flip the housing over and remove the three indicated screws from the back.

-

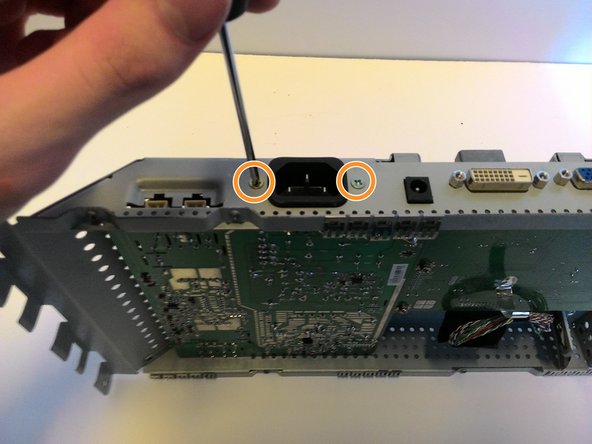

Flip it onto its side and remove the two screws attaching the powerboard to the power port.

-

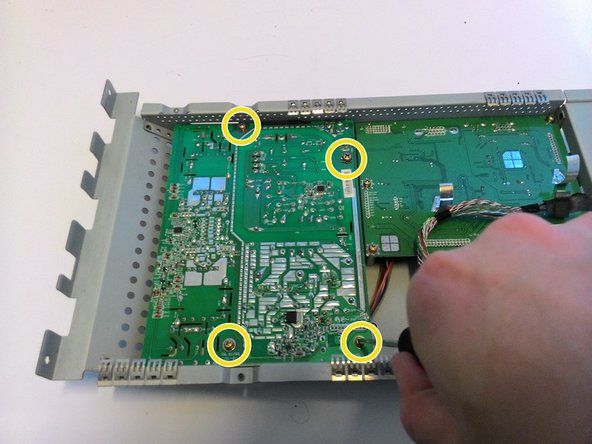

Remove the four screws from the powerboard itself. This frees the powerboard from the housing.

-

-

-

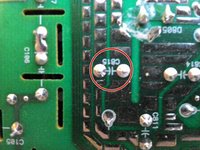

Now you can remove and manipulate the circuit board.

-

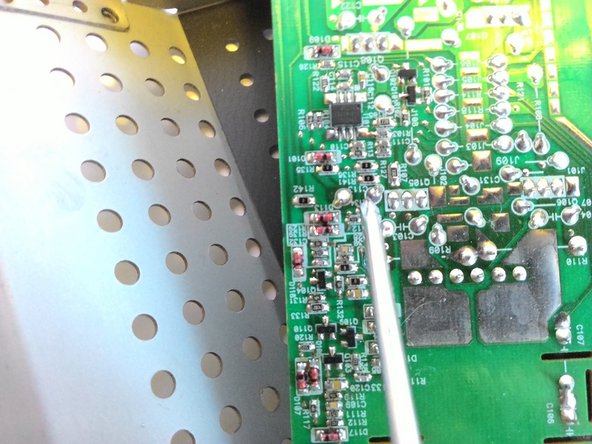

Locate any capacitors that are blown. The tops will be rounded rather than flat or could have dried orange fluid spilling from the tops. These need to be replaced. Identify their capacitance and voltage and remember these.

-

Using a soldering iron and desoldering tape, remove the solder attaching any blown capacitors.

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

4 other people completed this guide.

1 Guide Comment

I seem to have a different board layout inside my DELL 1905FP. Maybe they differ internationally because of the built-in transformator.

Found and replaced the faulty capacitors on the transformator board. It is aliiiive :)

Thanks for the guide. Opening the case from the front frame first was the trick, I was looking for.