Introduction

This guide will show you how to remove the cylinder that encases the traveling valve and foot valve.

What you need

-

-

Remove the above grade riser pipe.

-

Firmly screw a T-handle onto the pump rod.

-

-

-

Use a pipe wrench to loosen and remove the pump spout.

-

Place the spout on a clean surface to prevent any contamination.

-

-

-

-

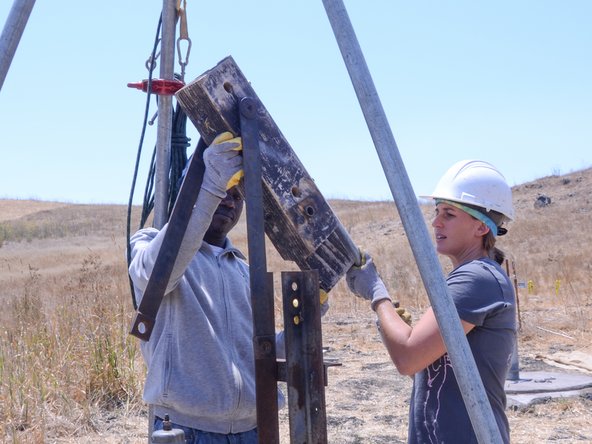

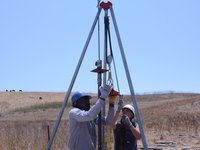

Place one wrench on the top of one of the pump riser plate bolts.

-

Place another wrench around the bottom of the bolt.

-

Pull the wrenches apart to loosen the bolt.

-

Conclusion

To reassemble your device, follow these instructions in reverse order.