This translation may not reflect the most recent updates from the source guide. Help update the translation or view the source guide.

Introduction

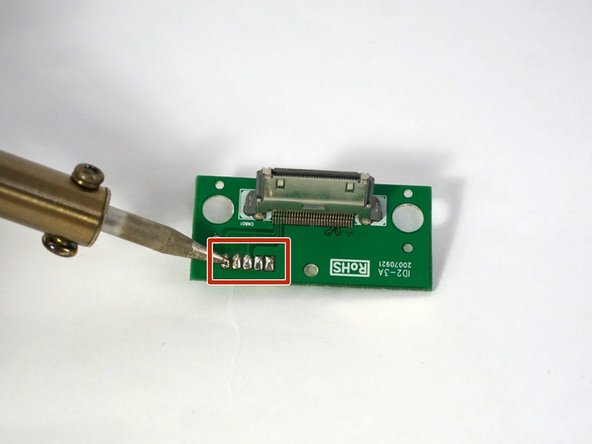

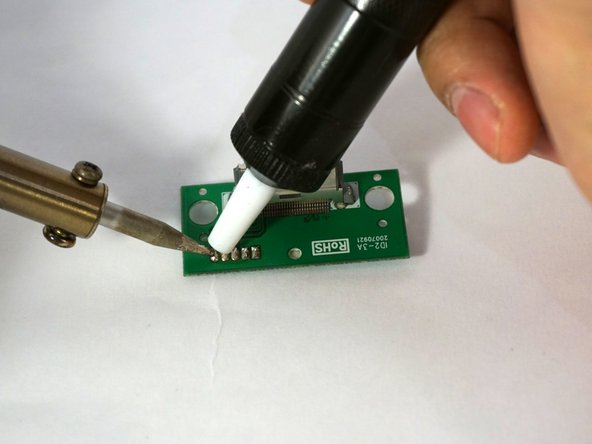

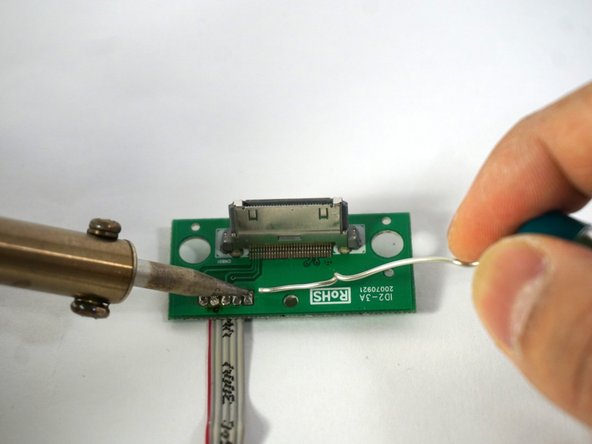

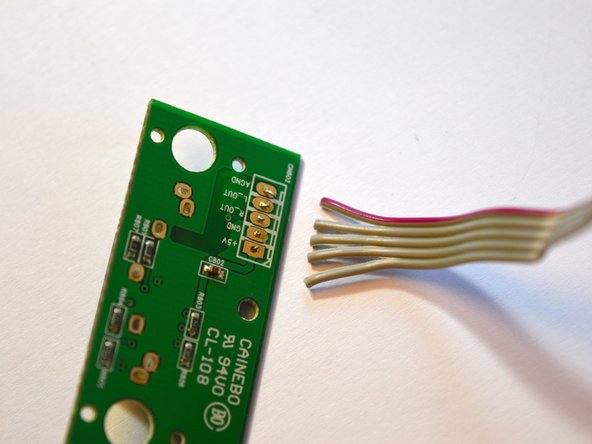

During this guide you will need some solder skills to repair the product. If you don't have any experiences in soldering, take a look at the How to Solder and Desolder Connections guide. Make sure you have all the tools that's needed to desolder en solder. Be aware of the fumes—do this in a well ventilated room!

What you need

-

-

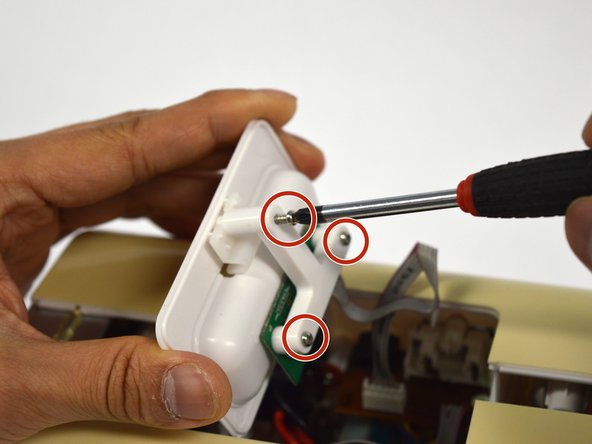

Unscrew the four Phillips screws on the backside of the docking system.

-

-

To reassemble your device, follow these instruction in reverse order from step 7

To reassemble your device, follow these instruction in reverse order from step 7

Special thanks to these translators:

94%

These translators are helping us fix the world! Want to contribute?

Start translating ›