Introduction

Use this guide to lift the casing pipe of an Afridev pump out of the pump in order to repair a broken or damaged segment of the pipe.

What you need

-

-

-

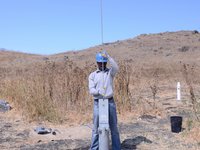

Grab firmly on the T-handle and lift the pump rod straight up.

-

Expose the first connection of the pump rod, and support the portion below the connection.

-

-

-

Place one wrench on the top side of the top base of the tank spout.

-

Place another wrench on the underside of the bolt in order to get more leverage.

-

Pull the top wrench to the right, and the bottom wrench to the left.

-

-

-

Slightly twist the head flange until the corners overhang the top of the tank, far enough so that you can grab them.

-

To reassemble your device, follow these instructions in reverse order.

Cancel: I did not complete this guide.

One other person completed this guide.

1 Guide Comment

It is much easier to lift the riser pipe AFTER you removed the foot valve. Removal of the foot valve requires use of the foot valve fish tool, being attached to the original rods (without using the piston and rod) and carefully lowered into the riser main. When it reaches bottom, turn it up to about 90 degree and see if it drops any during that turn. Then pull up sharply to remove the foot valve from its seat, and proceed with removing all the rods, fish tool and foot valve. When the foot valve comes off the seat, you may hear water running down the riser pipe, this is not a problem. That water was just being held above static water level by the working foot valve.