Introduction

You probably talk more to this device than your significant other. In fact, you probably talk to it the most out of any human or device in the world. It's your phone's microphone, and it's time to take a closer look at this wonderful creation.

We take microphones for granted. The majority of us use them on a daily basis without bothering to recognize their existence. They do so much for us, but we never get to see them or bask in their beauty. Until now.

We've partnered with Chipworks to reveal to you the multiple microphones contained inside an iPhone 4. There's nothing super-special with these mics -- they're not magical, nor do they contain Steve Jobs' fairy dust -- but they're good representatives of what you can find in today's smartphones.

-

-

The iPhone contains three microphones: two in the phone itself, and one in the included Apple earbuds. Given the orientation of the microphones in the device, we assume that one is for making calls and the other intended for capturing video and noise cancellation.

-

The iPhone 4 handset has Knowles S1950 and Infineon 1014 microphones (pictured on the left), while the earbuds contain a Knowles S199 mic.

-

-

-

The first of the two microphones inside the iPhone (the one that you speak into) is the Knowles S1950.

-

Knowles describes its MEMS microphones as being built with a patented CMOS/MEMS technology that allows for very small footprints, lower profiles, and several mounting options.

-

Translation: This microphone is very small -- a 3mm x 4mm footprint! And it's surface-mount, which means that a machine just pops it onto the logic board for you.

-

From a manufacturing viewpoint, a surface-mount design is valuable because it allows the components to be integrated to the logic board all at once. This eliminates sub-assembly costs, and lowers the BOM cost. It also allows us to have components on both sides of the board, something that's not possible with thru-hole technology.

-

-

-

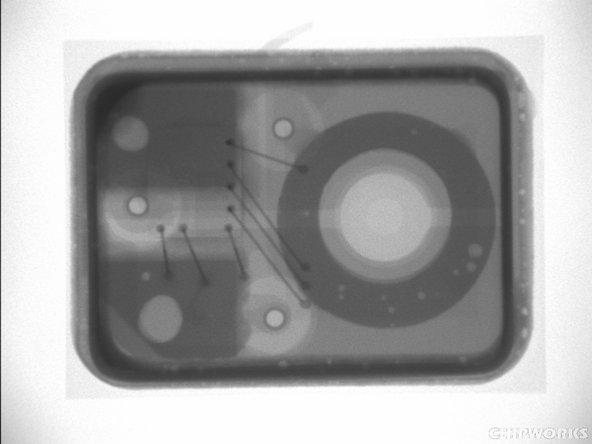

The Knowles S1950, like the other microphones in the iPhone 4, is comprised of two main parts: the MEMS and the ASIC. You can think of it this way: the MEMS does all the work, and the ASIC does all the thinking. Together, they make an awesome microphone.

-

Looking at the S1950 MEMS die gives you an idea of how it functions. Like a microscopic vesion of a condenser microphone, the microphone itself has a simple design, comprising of two parallel polysilicon plates (very thin plates made of multiple small silicon crystals) that act as plates in a capacitor.

-

The upper plate is perforated with an array of small holes, and is separated from the bottom plate by a small air gap. As the sound waves from someone's voice hit this top plate, it deflects very slightly. Because these two plates hold electric charge, these deflections cause minute changes in the electric field between the two plates. The fixed bottom capacitor plate senses and relays these changes as an analog signal.

-

-

-

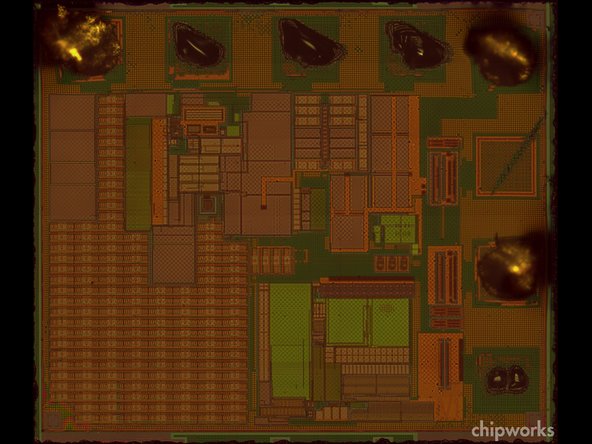

The S1950 ASIC die interprets the analog signals given off by the MEMS die. This portion of the microphone decodes and process the analog signal sent to it from the MEMS and sends the result to the iPhone 4's processor.

-

Because the microphone has this built-in analog-to-digital converter, the microphone package is very easily integrated with other digital circuitry.

-

-

-

-

Infineon manufactures the 1014, the second microphone in the handset. The giant chip maker is a relatively new entrant into the MEMS market, which was dominated by startup companies until about a year ago.

-

The industry underwent a lot of change recently, as MEMS devices have gone mass market. Large manufacturers like Infineon have started making MEMS microphones and Akustica (one of the original startups) has been acquired by Bosch.

-

The Infineon unit looks quite similar to the Knowles unit externally. Yet, each company works their own magic on the inside.

-

-

-

The die photo for the Infineon 1014 ASIC doesn't reveal too much about its functional layout -- there is a large metal layer over the circuit.

-

The metal layer could be acting as a ground plane or might be used RF shielding; or it may simply stop folks from looking at the die circuitry now that teardowns are getting popular.

-

But don't worry, we got you

uncoveredcovered. Chipworks had no problem removing the metal layer in order to expose the ASIC die.

-