Introduction

Please find the full blown teardown on our blog:

https://novemberfive.co/blog/hardware-te...

Since their first connected weighing scale back in 2010 (the WiFi Body Scale) I was a big fan of Withings.

All the products they make are beautiful, integrate seamlessly with their platform and they just keep on working.

The scale I bought in 2010 actually still works but I recently bought the new Body Cardio just because I wanted an upgrade.

Therefore I chose one of their products, the Withings GO, and took it apart to see how it looked on the inside.

What you need

-

-

From left to right: silicone wristband, clip, tracker and plastic coin to open the casing

-

-

-

You can simply open the back of the casing with the included tool or with a regular coin to remove the battery

-

The battery that is used is a Panasonic 3V CR2032 with a capacity of 225mAh

-

Removing the battery also exposed a seal ring used to make the enclosure waterproof.

-

FCC ID: XNAWAM02

-

-

-

The casing itself consists of three parts: the top, the bottom and a thin cover for the e-ink display.

-

Separating the parts seemed tricky at first, because they were sealed together, but by chipping some plastic off the side with my utility knife I managed to create a small opening. After that, I could easily cut open the casing around the seam.

-

-

-

-

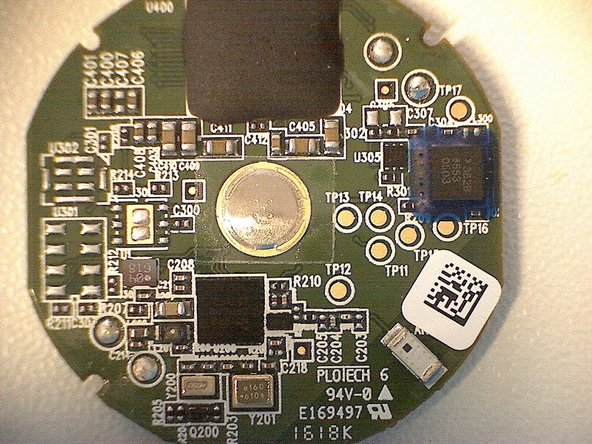

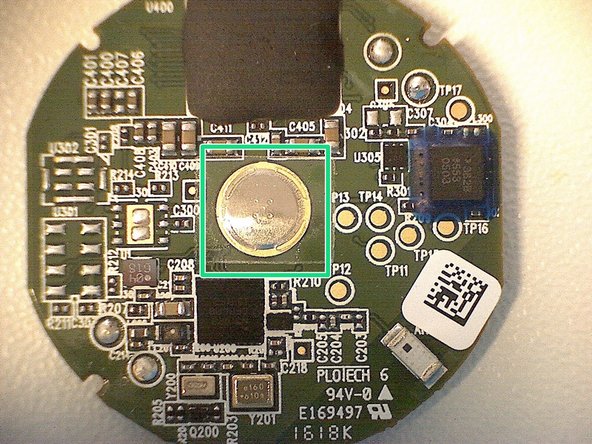

The PCB was manufactured by a Chinese company called PLOTECH

-

The back of the PCB immediately shows a bunch of testing points which are labelled on the silkscreen layer with TPXX.

-

The connectors Withings used are called "Front Flip FFC/FPC Connectors" and are very easy to open with a pair of tweezers. (FFC stands for Flat Flexible Cable).

-

Between the e-ink display and the PCB there is a support frame installed, this to keep the display in place and to avoid contact between the display and the PCB components.

-

-

-

On the top side of the PCB, in the middle, there is an SMD push button. The display is so thin and flexible you can actually press the button with it.

-

-

-

-

The bluetooth chip Withings has chosen is the nRF51822 from Nordic Semiconductors. It's a 2.4GHz ultra low-power bluetooth chip built around a 32-bit ARM® Cortex™ M0 CPU.

-

The big white SMD component you see on the right side of the PCB is an RF ceramic chip antenna from Johanson Technology (datasheet).

-

Below the bluetooth chip there are two crystal oscillators. According to the datasheet of the nRF51822 the system uses 2 clocks: A high frequency clock (HFCLK) and a low frequency clock (LFCLK). The HFCLK is fixed to 16 MHz and the LFCLK is fixed to 32.768 kHz.

-

The balun, BAL-NRF02D3 (datasheet) from STMicroelectronics, next to the bluetooth radio is used to match the impedances. This balun is actually optimized for the nRF51822. Read this blog post to understand why a balun is used in this circuit: https://devzone.nordicsemi.com/blogs/655...

-

-

-

The big black "blob" (glob-top) on the top of the PCB, is what I assume the display driver. The blob is actually a protective cover for the chip and the wire-bonds. This type of method is called "chip-on-board" (COB). Black epoxy resin is used as the chips can be sensitive to light, it's the same material used for the packaging of ICs.

-

-

-

The display is only 0.45mm thick, that's very thin! The display does contain a serial number "SCD72E00-160418-1". The company eink is the manufacturer.

-

One Comment

I have a bunch of CR2025 batteries, because I use them in various other devices. Could I use CR2025 in Withings Go instead of CR2032?

I for sure know about the difference in capacity and thickness.

Life expectancy of CR2025 could be approx 5-6 months I think.

I just ask you if it is possible in respect of adaptability of contacts in battery holder or its mechanism.