Introduction

The surface keyboard is one of Microsoft's attempts at bringing a laptop-style keyboard to the desktop space. Originally introduced alongside the Surface Studio, this keyboard has been equally championed and hated by various technology reviewers. This teardown will provide some insight into the keyboard construction and Microsoft's design decisions.

What you need

-

-

The box is a scaled representation of the product. It's pretty much spot on.

-

It's a box - no It's a keyboard - no it's a box...

-

-

-

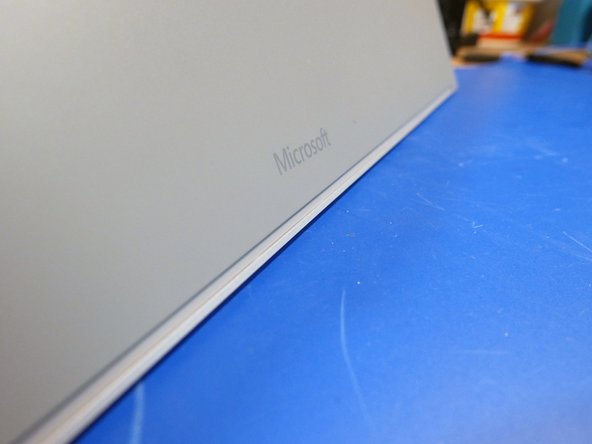

Before I tear apart a product, I like to take the time to analyze the exterior construction and overall build of the item. This gives me a better idea of how the product was assembled and mass produced.

-

The best way to do this is by looking for seams or imperfections in the build construction.

-

Does the part bow or flex when a small stress is applied? Are there any large gaps in the build? Are there any obvious stickers covering fasteners?

-

This is how I pictured the keyboard to be constructed in my head. I had a feeling that it was one gigantic glued and snapped together assembly, but I needed to verify that first.

-

-

-

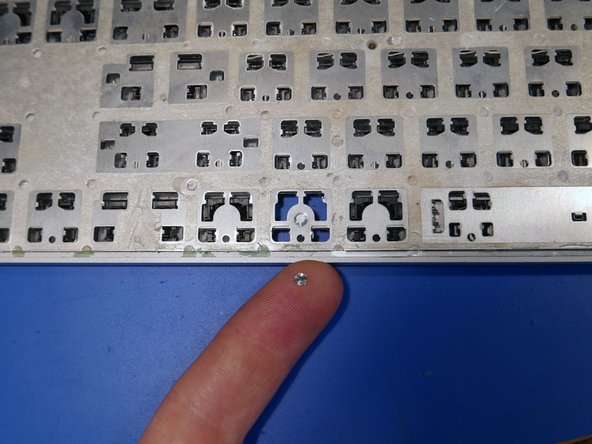

It would be quite underhanded to put screws under the keys. Luckily that is not the case here.

-

To remove a key, wedge a plastic spudger under the key from the top most edge. Apply a bit of downward pressure on the spudger to lift the key. The key should make popping sounds and unlatch from the metal clips underneath the key that hold it to the keyboard frame.

-

-

-

-

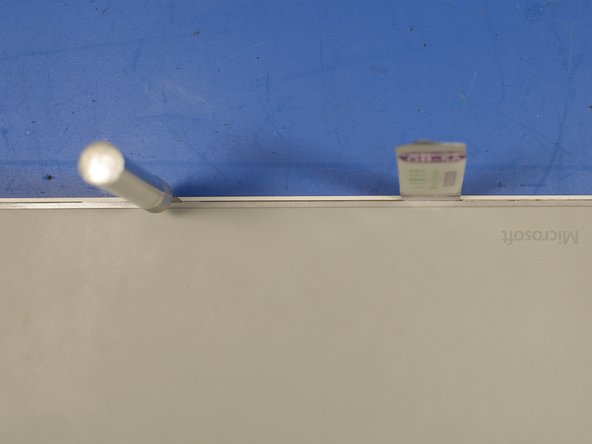

With the amount of double sided tape and glue inside this keyboard, it would be wise to use an iOpener tool or heatgun before beginning to pry open the keyboard.

-

I used a heatgun a bit later into the prying process because I was fearful of melting and deforming the back plastic of the keyboard. Luckily, adjusting the heatgun to its lowest setting activated the glue enough to become pliable.

-

-

-

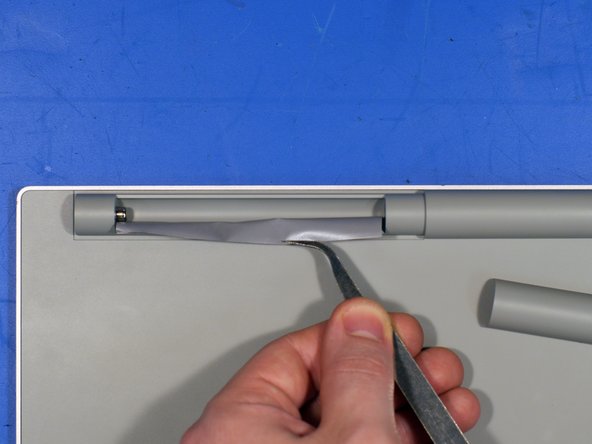

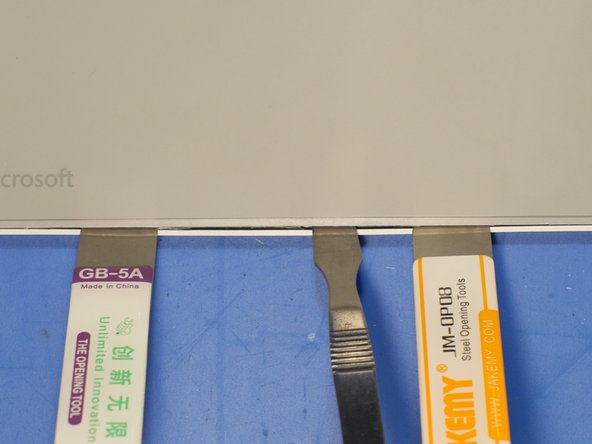

Now for the prying bit. Ready your barrage of prying tools! I used plastic spudgers, metal spudgers, plastic cards, and X-ACTO knifes to get this open.

-

The gap between the aluminum shell and plastic rear plate was so tight I had to use an X-ACTO knife with square-headed No. 18 Blade to widen the gap enough to slide in my metal spudger.

-

-

-

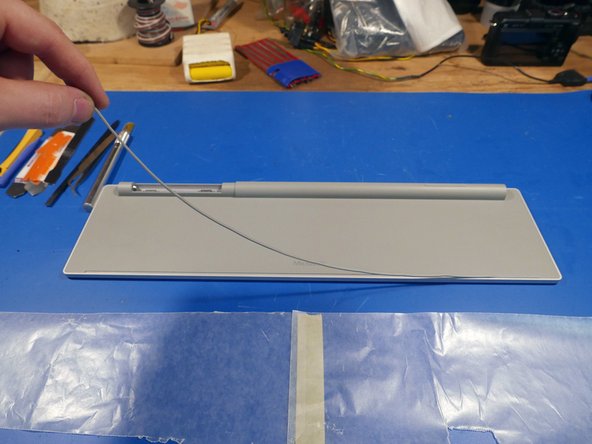

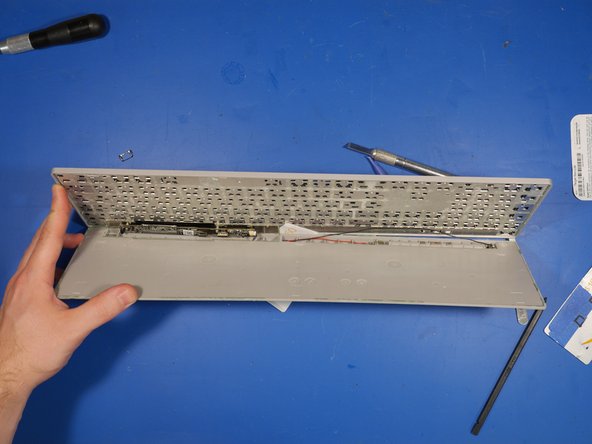

The two main halves started to separate with some persuasion.

-

Giftcards really come in handy. They allow for some prying action without damaging sandwiched parts. If I used a metal spudger for this step, I could have risked tearing the one ribbon cable inside this keyboard. Save your giftcards!

-

-

-

Close-up on the Battery compartment.

-

Neodymium magnets on both terminals and the top of the compartment!

-

The top magnets actually hold the AAA batteries to the top part of the plastic battery section. The only way to easily remove the batteries from the housing is to forcefully tap the top of the keyboard.

-

-

-

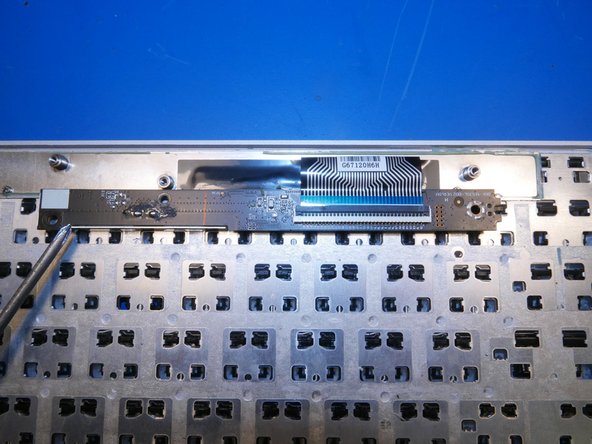

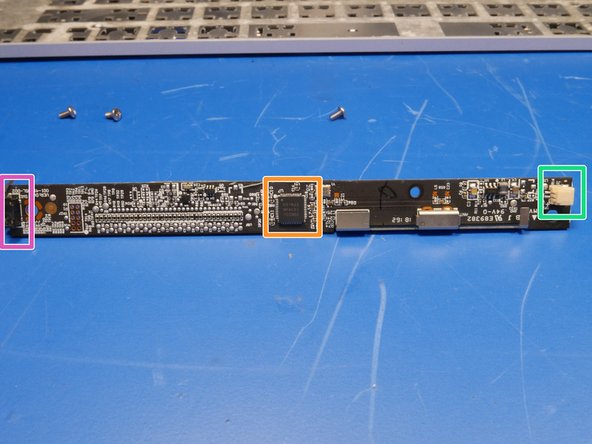

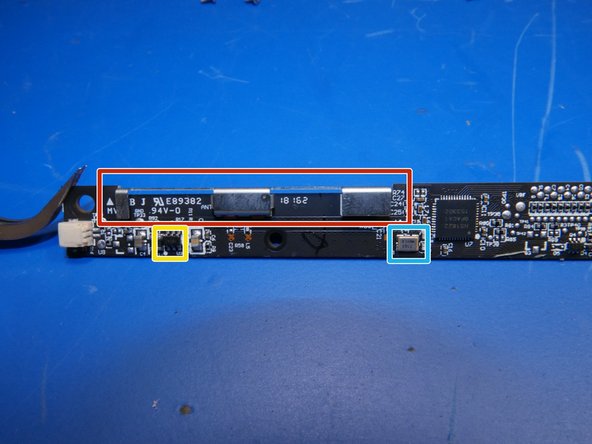

A closer look at the Bluetooth antenna. Even though this looks more like a bracket than an antenna, it has been sized appropriately for the 2.4ghz bandwidth.

-

Real-time clock

-

Microchip Microchip VUA Power IC / Voltage regulator

-

-

-

It is rather interesting that Microsoft intentionally left an empty ribbed space in the bottom compartment of the keyboard.

-

The Microsoft Modern Keyboard anyone?

-

-

-

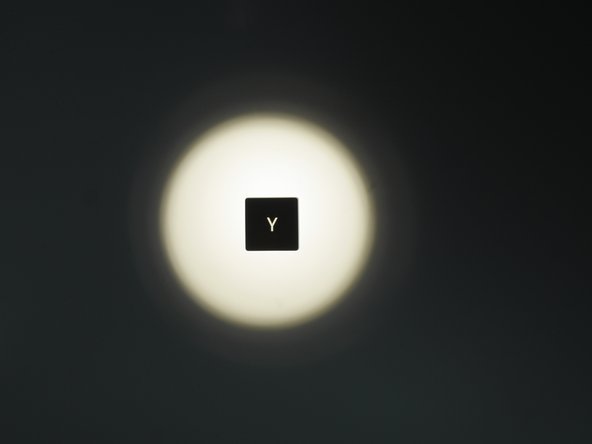

One of the biggest complaints of the surface keyboard is that it doesn't feature a backlight.

-

It is rather sad that Microsoft chose to design a keyboard with several intentional iterations in mind, instead of just producing the best slim keyboard they could.

-

A quick design change such as adding a hole under each key, an optical diffusing layer and a few LEDs would have added a simple and functional backlight.

-

For further investigation into this keyboard, check out my Surface Keyboard Hacking Project

-

Cancel: I did not complete this guide.

9 other people completed this guide.

17 Comments

Man, how rude to use glue for a keyboard! I wanted to open my Surface Ergonomic keyboard in hopes it had JTAG or other diagnostic port that would enable me to twiddle with its brain, since macOS does not believe it is a keyboard but rather just a generic bluetooth HID :(

Thank you for sacrificing your keyboard to spare me the pain of discovering the hard way that my keyboard is glued together

No problem! I’m glad you enjoyed the teardown. I sure wish they used screws instead of adhesive. It would make retrofitting a backlight far easier.

If I discover anything interesting from probing that 10 pin unpopulated header I’ll be sure to provide an update.

hey Anthony, i have the same problem with one of the keys (the big “0” on the numerical part). Did you find a solution for fixing the “key tabs that hold the key” that sheared of of mine as well?

Hi Bas! Unfortunately, I did not attempt to repair the broken aluminum key tabs that hold the key in place. However, I can point you in the right direction if you want to get creative and try a DIY fix. Carefully pop another key off your keyboard with something wood or plastic (like a plastic spudger) and analyze the metal locking tab design Microsoft implemented. Find another piece of aluminum of the same thickness and carefully cut out that tab shape. Try adhering your designed tab to the location where the broken aluminum key tab is situated. Epoxy or titanium putty should bond aluminum to aluminum. I would use a toothpick or sewing pin as an adhesive applicator. I think you will have success if you take your time and be patient. Good luck!