Introduction

You will learn about how the unit is engineered, and how to do a partial disassembly. Note: This describes the heating/cooling which is part of 2nd generation ChiliPad / ChiliCube system (introduced in 2014(?), and not the first generation unit (mostly sold pre-2015) which was more squat, and had a handle on top.

What you need

-

-

Unhook the cube from power and from the circulating tubes connecting it to the mattress pad.

-

Drain water from the cube. (not completely necessary if a little dribbling is OK.)

-

-

-

Note that one of the screws we need to remove is under the "QC Passed" sticker. If you are still under warrantee, and you don't want ChiliTechnology giving you grief for messing with something you own, slide a razor under the "QC Passed" sticker, and "store" it by parking it on one of the other stickers on the cube.

-

Since 2 out of 2 of your editor's ChiliCubes needed to go back for repair during the first year, You'd better treat that sticker nice!

-

-

-

Notice hole with red arrow pointing to it. This is the reset for what is probably a thermal breaker. According to ChiliTech support, you stick a (very long) pencil down here to reset the breaker, do this if the heater on your cube does not work. (or works poorly.)

-

Resetting the thermal breaker might take several tries, its hard to tell if you did it right. It seems to be a mechanical thing, and not a microswitch like you might use to reset your router.

-

You need that heater, because ChiliTech has changed the instructions for the cube since 2014. Now you need to be able to turn the heat up to high (even if you only use your cube for cooling.)

-

Every month, they recommend 1/4 cup of hydrogen peroxide and run it at 90º for 20 minutes.

-

Every 3rd month they want you to put 1/4 cup of hydrogen peroxide in, and run the cube on high for 6-8 hours.

-

Better invest in stock in peroxide and distilled water companies!

-

This is all to cook the bacteria that grows in these things. Don't tell your spouse if they are squeamish about that sorta stuff, just tell 'em you are experimenting with a new way to brew beer.

-

-

-

Remove 10 screws. Four of them are in deep narrow holes which presumably are intended to prevent casual disassembly like this. You will find most regular #2 philip's screwdrivers are not long and/or narrow enough.

-

-

-

Unhook connector for small ribbon cable which connects control board on top of cube with circuit board on bottom of cube.

-

-

-

-

Here is what cube looks like from back, side and front.

-

From the back, you can see the ports for the circulation hoses at the bottom, the water reservoir above, surrounded by insulation foam, and heat sinks left and right. Its not clear if you can remove the heat sinks without damaging the reservoir.

-

There is the left-side fan. Noisy! Look to my guide to fan replacement to make your unit quieter.

-

Those are probably thermostats on top of the heat sinks.

-

-

-

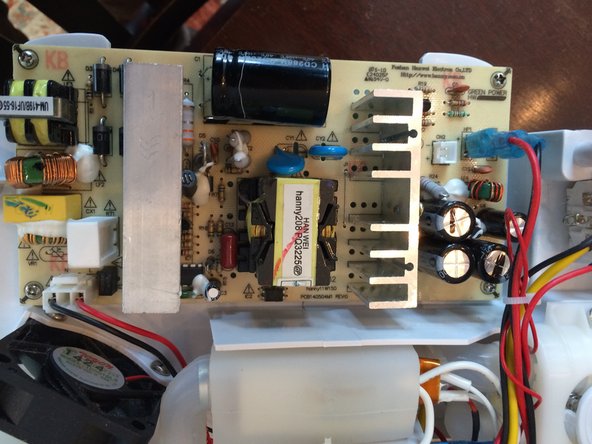

Underneath, where most of the electronics are located. This hangs upside down during normal use.

-

Note that there is actually a third fan in every unit to cool the power supply (and pump?). Luckily this fan is quieter.

-

-

-

Your author's cubes both had this thin red cable floating with one end loose. This is the antenna for the wireless control. (Radio as opposed to infrared like your TV wireless control, because you may not have good line-of-sight.)

-

Water pump, and small fan.

-

Power supply.

-

-

-

As you will see, the fans in this unit are not designed for easy removal or replacement

-

The 2 screws supporting the fan are on the heat sink side of the bracket/shroud, so we remove the bracket first, so we can get to those screws next. Remove four screws holding the bracket/shroud to the heat sink.

-

-

-

The fans are connected in series to a single header on the main circuit board. You can not do a tool-less (or even splice-free) replacement of the fans.

-

The fans are connected to one another, and to the circuit board via a path under the "deck" (actually above, when right-side-up.) There are cable ties way underneath, and to get to that, you would need to disconnect almost everything else on the cube, including the pump and all of the circuit boards.

-

-

-

Unwilling to disconnect the pump, your author instead has just demonstrated what would be removed next. You must remove 3 screws anchoring the pump.

-

There is a bit of play with the silicone tubes connecting the pump to the resevoir once the deck is disconnected

-

The pump has got some stand-offs and silicone grommets to isolate vibrations from the rest of the cube to keep things quiet.

-

-

-

Remove 4 screws apiece from the main circuit board, and the circuit board for the power supply.

-

Once the pump and those boards are removed, you can access the 4 screws attaching the deck to the heat sinks and reservoir.

-

-

-

Once the deck is loose, you can lift it a tiny bit to see the wiring harness underneath. The pump above the deck is still connected to the reservoir below the deck through holes in the deck, so there is not much play.

-

Notice that the "deck" has a flange at the edge, and surrounding each of the penetrations to the deck. When this is right-side up, these flanges will supposedly capture any water which happened to spill between the filler neck and the case, or slight internal leaks elsewhere, thus preventing the water from getting to the electronics.

-

Mind you, the splices for the fan harness would be sitting in any puddle captured by the deck (but at least that would only be low voltage DC.)

-

The fans must be connected together and their wiring cable tied together before the pump is attached in the factory, meaning you are forced to cut the wires to replace them unless you completely disconnect the deck and the pump.

-

-

-

Your author was unwilling to disconnect the reservoir from the pump or heat sinks, so there are some parts of this cube which will remain unseen until it dies for good.

-

The best view possible for the thermal breaker reset switch.

-

Connectors to main circuit board, black is pump, red is small fan, white is harness for two large fans.

-

-

-

Added a couple of pictures of the elusive thermal breaker. There are two black wires connected to the thermal breaker. The wires are connected together under normal conditions (closed circuit) and separated (open circuit) when the breaker detects a thermal issue.

-

108 Comments

I haven't needed to replace my pump, so I do not have that info. I would 1st suggest contacting Chili, but according to an Amazon reviewer for the previous version of their cube, they were completely unhelpful.

Based on the markings on the pump in my photos, I came up with the following requirements to find a pump:

o 0.24 Amps at 24 V DC, which means it should not consume much more than 10 watts 24 DC

o 6 Liters/Minute, which is 1.5 Gallons/minute, 360 Liters/hour, or 95 Gallons/hour (GPH). I think that measurement is taken with a head of 2.2Meters or 7.2 feet (head means the vertical distance water is moved)

o A centrifugal pump which has mounting pads and can be rigged like ours. You will have to disassemble the pump I found and rotate the inlet/outlet cap 90 degrees. I hope it goes in right direction...

This from amazon may work:

Reply & let us know what happened (I'll write it up if you want), tell us if that part worked!

Do you have an idea how the unit actually cools the water? What I gather from your pics is that it's just conductive heat transfer to the large heat sinks (somehow) as the water warms up? Mainly does it actually have a mini A/C compressor in it or anything? Or does it just cool by pulling ambient air across the heat sinks. Thanks!

It isn’t just cooling to ambient, it is using thermo-electric (Peltier) cooling.