Introduction

UK style plugs are notoriously treacherous to bare feet—when dropped they almost always land points-up, making them the LEGO of the power distribution world. Not only that, but they're big, and inconvenient to throw in your bag to charge your devices on the go. Apple finally put its engineering might to the task, and developed the all-new, highly superior folding plug. The more compact, more foot-friendly variant.

But how does it work? What's behind that shiny white plastic? Read on to find out.

What you need

-

-

Released with the Apple Watch in the UK / HK, the new folding plug has pins that fold completely flush for travel.

-

Matches the older style plug with a 5W / 1A specification.

-

AC 100 - 240V input.

-

-

-

Becoming more common on mains chargers, most of the design is fastened together during the moulding process. There is only a single screw (Torx T9 M2.5 x 2.75mm) in the entire product.

-

You could possibly pry this open, but you would likely make a big mess. Instead this has been cut in two using a fine bladed coping saw.

-

This was cut 1mm behind the USB port entrance.

-

Inside we can see the design has been split into two halves.

-

All of the electronics are on a single PCB on the left.

-

All of the mechanism and high voltage contacts are on the right hidden under plastic hood.

-

-

-

A break down of the top side of the PCB:

-

Rubycon 4.7µF 400V electrolytic capacitor 400AX4.7M8X9

-

Fairchild bridge rectifier MB10S

-

Everlight optoisolator EL3H7-G

-

Transformer markings 157-00003 / HIG J 1503

-

-

-

-

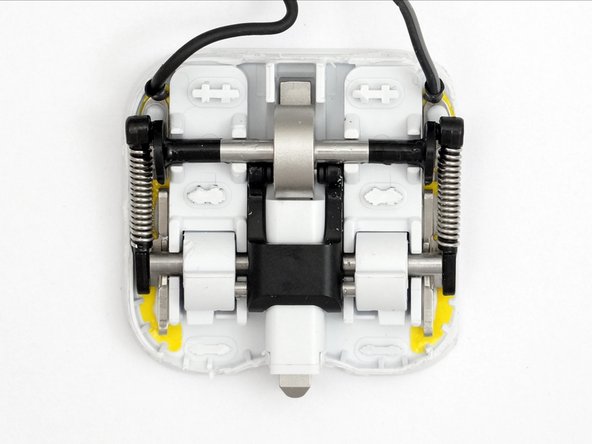

Finally we can see how the mechanism works!

-

The yellow tape is Polyimide high temperature film.

-

The cover is needed for the mechanism to work properly - the central black plastic piece will lift otherwise.

-

-

-

With the side of the bottom section filed away, you can see the stackup of the PCB, mechanism and contacts exposed.

-

The Apple folding charger repairability Score: 1 out of 10 (10 is easiest to repair)

-

Almost everything is moulded together during manufacture, making it impossible to take apart without damage.

-

-

-

A short render of the mechanism showing how it works, contributed by Thang010146 on YouTube

-