What you need

-

Step 1 PREHEATING THE MACHINE

Careful: steps 1-6 are sourced from a guide that's marked as in-progress.

-

ON the power switch.

-

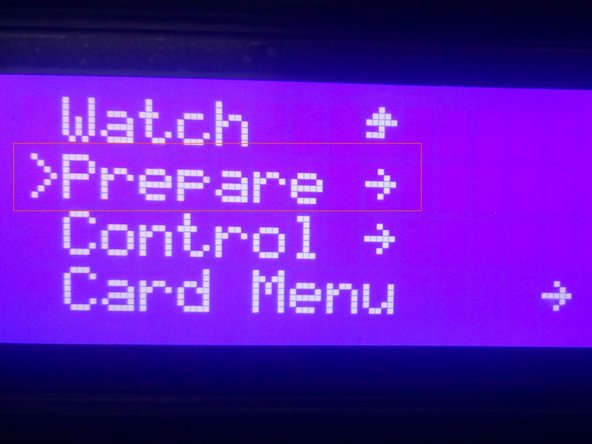

Go to prepare .

-

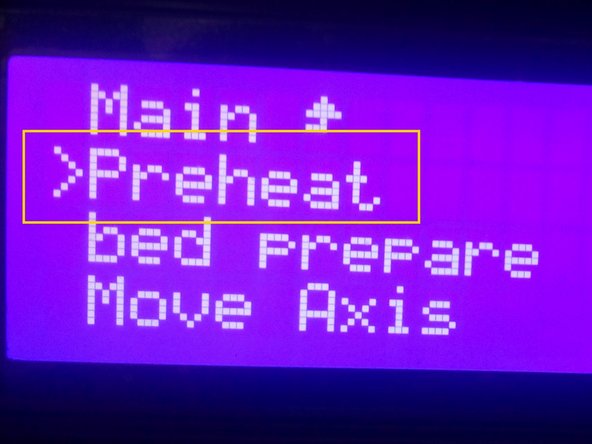

Click the option , preheat.

-

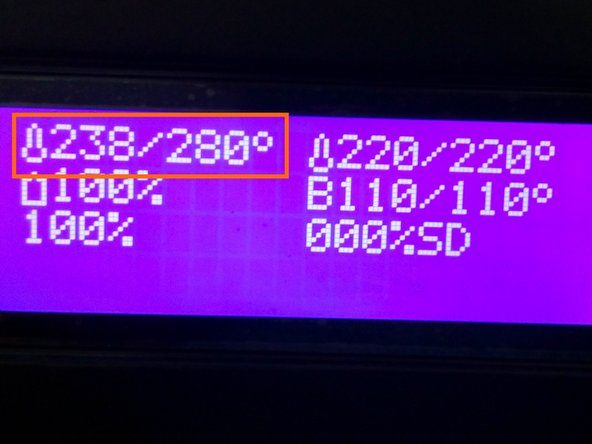

Go back to the main menu, check whether the nozzle temperature is increasing to the set temperature.

-

-

-

Remove the teflon tube from the nozzle block.

-

In some case the teflon tube will not come out free. In this case, increase the temperature to 280 deg and try to remove the teflon tube.

-

-

-

-

Take the needle, and try to clean it from the top of the nozzle block.

-

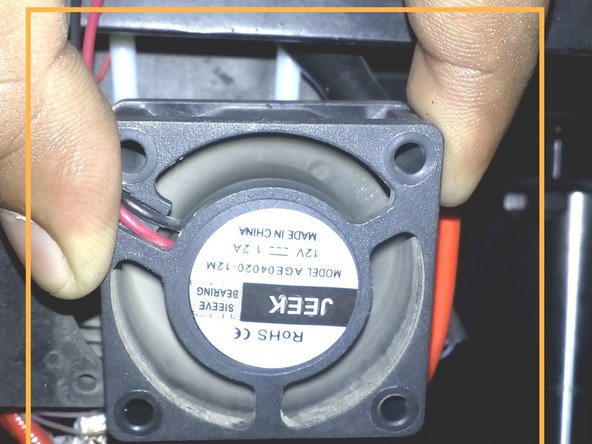

In some case, jammed filament will not come out free. At this case , increase the nozzle temperature to 280deg and remove the nozzle cooler fan.

-

And try to clean the nozzle from the top with the help of a needle and a nose plier.

-

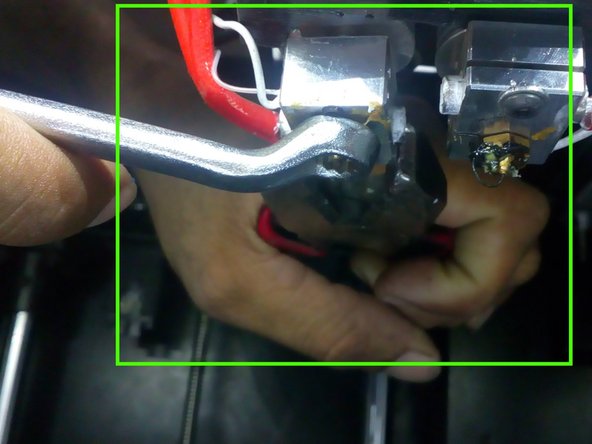

If the nozzle is again not clean, try to clean the nozzle by removing the nozzle tip with the help of a nose plier and spanner. Again clean it with the help of a needle.

-

NOTE: Be careful while removing the nozzle tip. If you extract more pressure on the nozzle tip, it may break. So be careful while doing it.

-

-

-

Reassemble the nozzle tip again with the help of the nose plier and spanner after cleaning the nozzle.

-

Reinsert the teflon tube.

-

-

-

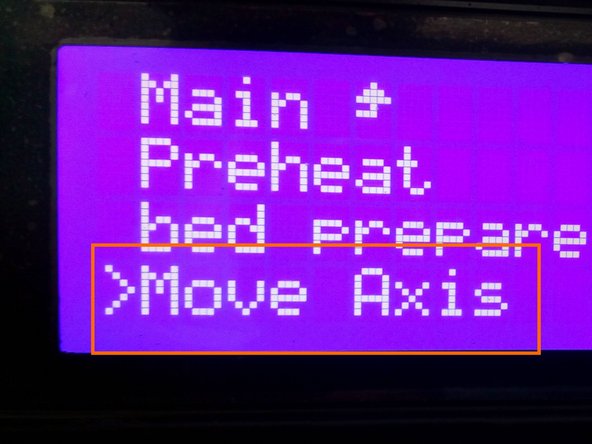

Go to prepare

-

click on move axis

-

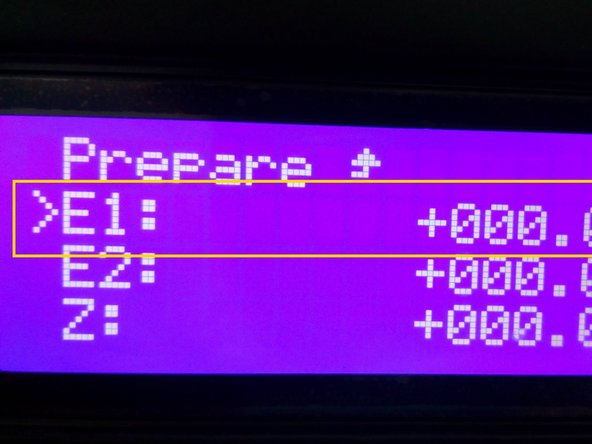

Select the extrude

-

Rotate the knob in clock wise direction and check the extrusion.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.