Introduction

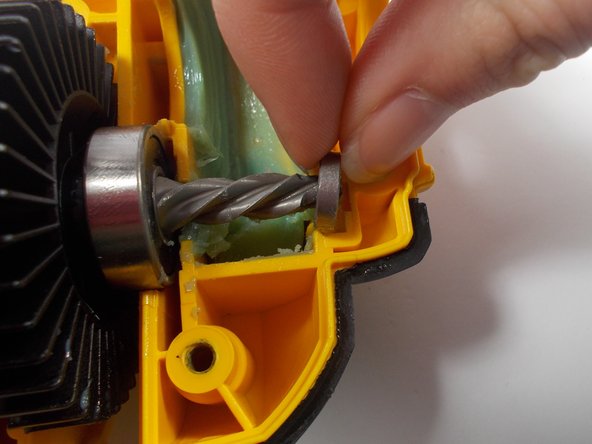

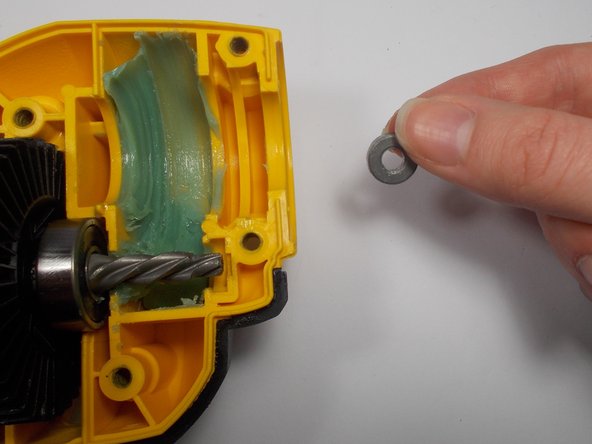

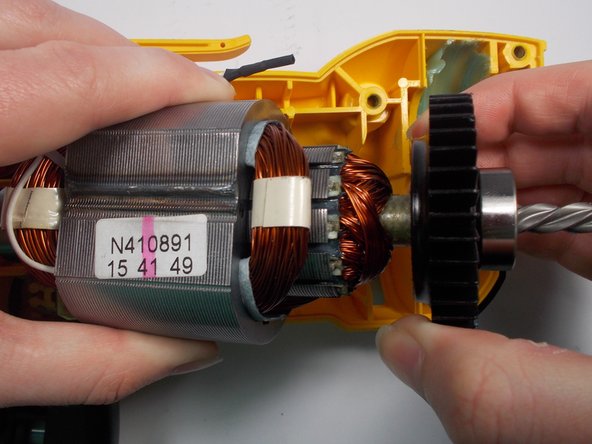

If the drill constantly becomes too hot to use, the cooling fan may be broken or clogged. Use this guide to replace the armature or fan of the DeWalt DWD112 drill.

What you need

Almost done!

To reassemble your device, follow these instructions in reverse order.

Conclusion

To reassemble your device, follow these instructions in reverse order.