Introduction

In order to remove the manifold assembly, you will need to nearly dismantle the compressor completely. Do not be alarmed, there are just a few key components involved in this to gain access to the manifold assembly. This fact should not hinder you from completing the repair. The guide is straight forward

What you need

-

-

Gently pull the wire attached from the pressure switch to the on/off switch.

-

It should come off the pressure switch with ease.

-

-

-

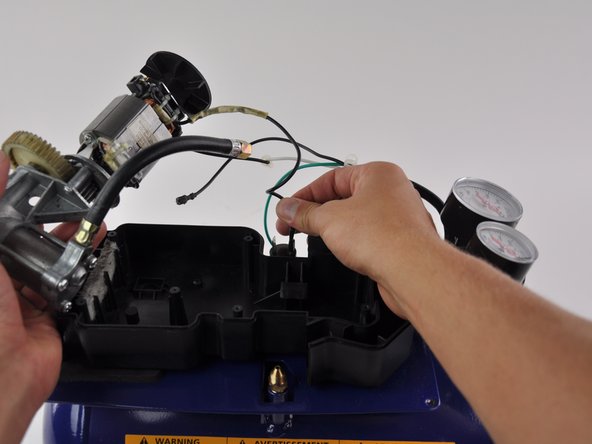

Gently pull the wire connected from the on/off switch to the motor of the compressor.

-

-

-

-

Unscrew the exhaust tube from the check valve using a smart wrench.

-

-

-

Unscrew the six 1.75cm screws holding the Pump/Motor Assembly Shroud in place using a phillips #2 screwdriver.

-

Remove the 1cm screw fastening the wires to the pump/motor assembly shroud using a phillips #2 screwdriver.

-

-

-

Remove the pump/motor assembly shroud by lifting it from the compressor.

-

-

-

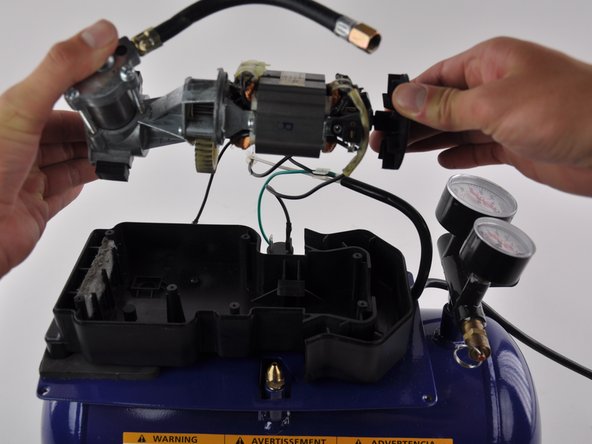

Gently remove the pump/motor assembly from the shroud.

-

Remove the wire attached from the motor to the pressure switch by gently pulling it free from the pressure switch terminal.

-

Set the pump/motor assembly on your work place next to the compressor.

-

-

-

Remove the four 1.5cm screws using a Phillips #2 Screwdriver.

-

-

-

Remove the bottom of the Pump/Motor Assembly Shroud by lifting it from the compressor.

-

-

-

Remove the manifold assembly by gripping the manifold stem with a smart wrench and twisting in a counter-clockwise direction.

-

-

-

Remove both the Pressure Gauges and the Safety Valve with a Smart Wrench by turning them in a counter-clockwise direction.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.