Introduction

Replacing the brake rotors and pads on your 2011 Dodge Journey will bring new life to your vehicle's braking power and smoothness. The brake system is a vital safety component for your vehicle, and while extreme care is needed during repairs, it is a repair that can be done in a few hours by yourself, saving hundreds of dollars.

What you need

-

-

Chock (forcefully wedge an object, such as a wood block, between tire and pavement) the wheel on the opposite corner of the wheel you are working on, so that the vehicle cannot roll forward or backward.

-

-

-

Using the ratchet and the 19mm socket, loosen each of the lugnuts 2-3 turns

-

-

-

Use the hydraulic jack to lift the vehicle, place the jack stand, and lower the car so that it rests on the jack stand.

-

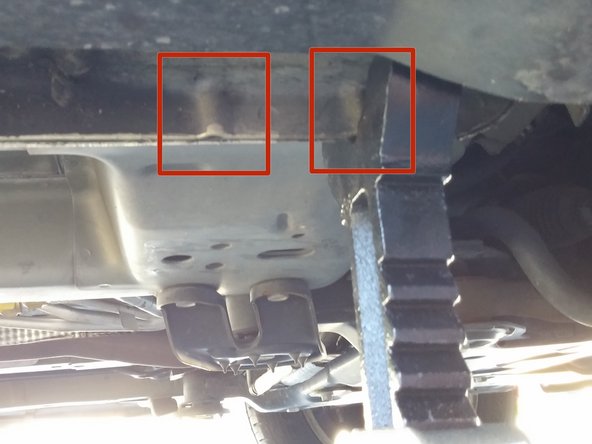

The bumps in the frame rail are the reinforced areas for lifting the car - lift at one of these umps circled in red, and place the jack stand at the other like in the picture.

-

You can now remove the wheel lugnuts the rest of the way and set the wheel to the side

-

-

-

-

Use the open end of the 15mm wrench to hold the slide pin, and use the 13mm wrench to loosen both bolts, then completely remove the bolts

-

-

-

Wiggle the caliper out and off of the pads/rotor, and place out of the way - do not let it dangle by the brake hose.

-

-

-

Remove the brake pads, being careful not to lose clips on caliper bracket.

-

-

-

Using the ratchet and socket (21mm for the front, 18mm for the rear), and remove the bolts holding the caliper mounting bracket. Again, it may be helpful to loosen both bolts before complete removal.

-

-

-

Pull the boot from the caliper bracket and slide the pin out to inspect. If there is heavy pitting or rust, you will want to replace the slide pins and bracket. Otherwise, lube with brake lubricant grease for reassembly.

-

-

-

A hard rap with the hammer at the location shown should dislodge the rotor from the hub. If not, try alternating hammer strikes back and forth from opposite ends of the rotor hat until the rotor breaks free.

-

To reassemble your device, follow these instructions in reverse order. Recheck wheel lugnut torque after 500 miles of driving.

To reassemble your device, follow these instructions in reverse order. Recheck wheel lugnut torque after 500 miles of driving.

Cancel: I did not complete this guide.

11 other people completed this guide.

One Comment

I was looking for the torque for both, the caliper pins screws, and the bracket screws. Any help on this? Thanks.